If you are reading this, you’ve probably already gone through the beginning of the Softpedia experience in Japan, an opportunity that we got once accepting Sony’s invitation to visit its Nagano facility. After having visited the Sony Museum in Tokyo, the guys at Sony decided to take us into their lair of technology, following a bus ride to their prestigious Nagano facility, in Azumino City. Long story short, we gladly accepted the invitation and after a couple of hours we were walking among some of the testing facilities in the Nagano factory, as detailed in our previous article.

We were now in front of a large metallic door separating us from this large chamber where the temperature was set at 35 degrees Celsius and combined with a 90% humidity level. This is where they test to see if a Vaio can continue operating while the weather outside isn’t as favorable. After a few minutes inside this chamber, we were anxiously looking for a way out and a breath of fresh air.

After all these test chambers, we were now heading towards some other parts of the Nagano facility. Some of which were actually pretty cool. First off, there was this verification chamber for Vaio keyboards. In this small room, a Sony employee was handling a large machine that was laser printing letters and numbers on the blank keyboards that were lying inside this carton box. The speed at which she was doing her job was impressive, as we might have seen a dozen or so keyboards being printed, while a Sony engineer was explaining the entire process.

In fact, what we found out during this part of the tour is that Sony can actually customize the keyboard of a specific laptop, with different fonts or special drawings on the keyboard, considerably boosting the cool factor of the laptop itself. We thought this was a pretty good marketing idea, which is why we asked them why this option wasn't available for Vaio fans. What we found out is that Sony was actually considering offering this choice to consumers in the States, but that is yet to be decided. Fortunately, Sony fans in the US can already take advantage of a customization option for their laptops, as they can engrave it with their personal message. If all goes well, maybe Vaio fans worldwide might get a chance to take advantage of this opportunity.

Following the whole customized keyboard facility, we were now guided to the place where all parts come together for the final assembly of the laptop. In a large room, a number of Sony employees were sitting in strategic places that enabled them to install and set different parts on a specific laptop. Like little robots, these people were taking chips and parts to assembly them on a laptop. It was impressive to see that, even with us right there taking pictures of their work, they continued to see about their business, with no interruption.

Each worker is specialized on a specific part of the laptop's assembly process, but Sony says it's ready to face the possibility of a worker getting sick. It is here that we were shown the laser soldering process that allows Sony to manipulate the amount of soldering solution being used, thus enabling thinner designs for laptop PCBs and other components. This entire miniaturization process you'll see throughout all of Sony's products, as the Japanese company is focused on providing some of the most unique designs on the market.

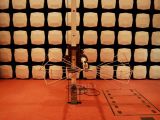

Further down inside the Nagano factory, we were presented to one of Sony's latest test facilities, one that had cost the company close to 1 million euros. This is a facility that enables Sony to ensure that every single product they roll out of the assembly line will be compatible with all the different wireless standards throughout the world.

Now, before we could set our eyes on the testing chambers inside this facility, the Sony engineer that was responsible for this part of the tour, showed us a large panel with all the standards that have to be met for each new Vaio. We can tell you that there are several such standards, but the large majority is within the European Union.

Following this small introduction, we were taken through each of these testing chambers. As you can see in the pictures below, these rooms are rather large and are designed to enable Sony to take advantage of their own, in-doors testing facilities.

After the Sony EMC Test Laboratory, we were once again in the briefing room, were the Sony Nagano team wanted us to leave with a nice impression of the entire factory and the people there, which is why all the journalists that went on the tour were presented with this customized Bluetooth Vaio Mouse. This is yet another example of what Sony can add to their products, letting Vaio users have that pride of ownership that's part of Sony's marketing strategy.

On a final note, you might notice, throughout the pictures in the gallery, a Vaio P portable laptop that looks a bit different than what you might know about the company's first Vaio P. In fact, that is the new ultraportable P-series from Sony, a product that we were able to get our hands-on just before the official debut of the series. We will have an updated article on the features and our experience with the new VAIO P, so stick around for more.

14 DAY TRIAL //

14 DAY TRIAL //