Despite foundries enthusiasm about moving to the 28nm fabrication node, most of them have problems with the introduction of the 32-nm/28-nm high-K metal gate (HKMG) CMOS technology, believe key industry execs.

"[Making] bulk silicon HKMG at 28-nm is hard. All foundries are having yield issues and defect density issues right now," said Bob Johnson, research vice president at Gartner who was cited by the EE-Times website.

Richard Wallace, president and CEO of semiconductor equipment maker KLA-Tencor Corp. seems to agree with Johnson as he also has a grim outlook about the 28nm node.

"Foundry players struggling with their yield issues at 28," said Wallace.

In addition to the low yields that affect the 28nm HKMG node, foundries also have to face a reduced demand for this technology, as companies have tighter engineering budgets due to the increased global economic uncertainty.

TSMC is expected to be one of the hardest hit foundries as it was aiming for a 20 percent annual growth in 2011, but at the end of the first nine months of the year TSMC's sales are 4.2 percent up on the equivalent sales in 2010.

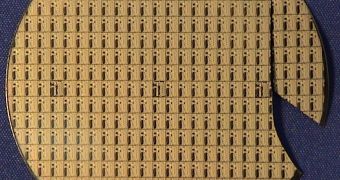

"In 2012, total 28-nm HKMG shipments will not exceed 200,000 300-mm wafers; or less than 4 percent of foundry' revenue. Shipments won't start until 2012 and its coming slower than people had previously thought," Johnson said.

TSMC has started the mass production of chips using the 28nm process node a little more than a week ago, but it doesn't expect for this to account for more than 2-3% of its total wafer sales in the last quarter of the year.

The foundry is also said to be hit by low yield rates even though it states that its new technology is doing better than its 40nm process at the same point in time.

14 DAY TRIAL //

14 DAY TRIAL //