You buy the latest digital camera, take a zillion pictures with it and store those captured instants on your HDDs or optical media. Many of those pictures surely look better on paper than they do on your display screen. But how do we transfer digital images or text on good ol' papery stuff? Printers, mound up! Let's show these guys how it is done!

The image crafter Let me do the honors. The computer printer is a device that produces a hard copy of electronically encrypted images or text on physical print media such as paper or transparent materials. Modern printers can directly interface to other electronic devices such as digital cameras, scanners or digital video recorders or they can read digital storage media such as memory sticks or memory cards. Some printers even integrate scanners and/or fax machines in a single unit, making for a multi-functional device. For example, a printer that integrates a scanner can replace much larger photocopier. The initial consumer printers were designed for low-volume, short-turnaround print jobs. That's why the 1990s printers were generally slow devices (10 pages per minute is considered to be quite fast and many consumer printers couldn't get over 2 pages per minute), and the cost-per-page was and still is relatively high. In contrast, the printing press, which basically serves the same purpose as a printer, is designed and optimized for high-volume print jobs such as newspaper print runs. Current printing presses are capable of hundreds of pages per minute or even more, and have an incremental cost-per-page which is a fraction of that of printers. Curious to know who used the very first printer? It was our friend Charles Babbage who, back in the 19th-century, constructed a mechanically driven printing apparatus for that PC ancestor known as the Difference Engine.

Current Printing Technologies As I said, during the 1990s, printers were quite slow and only delivered satisfactory results. As various technologies got more and more perfected, consumer printers started to perform faster, yielding better results. However, while printers may be decently priced, the related supplies may sometimes cost more than the printer itself. Let us take a look at the current printer technologies.

1.Toner-based laser printers Laser printers produce high quality prints at good print speeds and these devices are well known for their lowest cost-per-copy. Laser printers are also considered the device of choice for many general-purpose office applications, but, when it comes to consumer adoption, it still remains an unpopular solution due to a high initial cost.

The first laser printer was manufactured by Xerox when researcher Gary Starkweather modified a Xerox copier in 1971. Since then, laser-printing technologies constantly brought billions of dollars for Xerox. The first commercial implementation of a laser printer was the IBM 3800 in 1976, used for high-volume specialized in invoices and mailing labels printing. This model was quite huge, taking up nearly an entire room, just like the early computers. Laser printers designed for use with a PC were released with the Xerox Star 8010 in 1981; however, although it was highly innovative, the Star proved to be far more expensive ($17,000) than other similar products. After PCs became more widespread, the first laser printer intended for a mass market was the HP Laserjet 8ppm, released in 1984. This model used a Canon Inc. designed engine controlled by HP designed software. The HP Laserjet printer was quickly followed by other laser printers from Brother Industries, IBM etc. A notable model was Apple's Laser Writer, which brought professional publishing techniques to PCs with the aid of specially designed Aldus PageMaker software. Today a laser printer that boasts enough memory, a higher print speed and duplexing capability can be acquired for about $300.

Jedis explain how the laser printers work Every laser printer goes through six basic phases in order to provide good results: - The charging phase - a corona wire (in older printers) or a primary charge roller projects an electrostatic charge onto the photoreceptor, which is usually represented by a revolving photosensitive drum or belt. - The writing phase - a Raster Image Processor (RIP) chip has to convert incoming digital images to a raster image suitable for scanning onto the photoreceptor. Jedis, ready you laser sabers! Steady... steady and off goes the laser, aimed at a moving mirror which directs the laser beam through a system of lenses and mirrors onto the photoreceptor. The laser thus creates a latent electro-photographic image on the photoreceptor surface. - The developing phase - the photoreceptor surface holding the latent image is exposed to a substance known as toner (very fine particles of dry plastic powder mixed with carbon black or coloring agents). These minute particles are attracted due to electrostatic phenomena to the photoreceptor where the laser scanned the latent image. Color laser printers add colored toner (usually cyan, magenta, and yellow, besides the black one) in three additional steps or passes.

- The transferring phase - further on, the photoreceptor is pressed or rolled over the sheets of paper, imprinting the image. - The fusing phase - the sheets of paper pass through a fuse assembly, which, due to having rollers that provide heat and pressure (up to 200 degrees Celsius), bonds the plastic powder to the paper. - The cleaning phase - when the printing process is complete, an electrically neutral rubber blade cleans any excess toner from the photoreceptor, depositing it into a waste reservoir, whilea discharge lamp eliminates the remaining charge from the photoreceptor.

2. Liquid inkjet printers Inkjet printers use ink-filled cartridges in order to spray very small, precise amounts of ink (measured in picoliters) onto the printing media. Inkjet printing (which includes the bubble-jet technology) is the most common consumer grade print technology. Inkjet cartridges feature an assembly of nozzles that produce very small ink bubbles that turn into tiny droplets of ink. The dots formed on the paper are the size of digital pixels, and thus this kind of printers can print high quality text and graphics. Modern inkjet printers have reached a point where they can go almost silent during the printing process. They also have a much lower initial cost than laser printers do, but this is balanced by a much higher cost-per-copy, due to relatively frequent ink refills or purchases of new cartridges. However, inkjet printers are slower than laser printers and the inked pages must be allowed to dry before being aggressively handled.

Inkjet technologies Currently, there are two main inkjet technologies used by printer manufacturers:

a) The thermal bubble technology is used by manufacturers such as Canon and Hewlett Packard. This technology makes use of tiny resistors to create heat, which in its turn vaporizes ink to create a bubble. As the bubble expands, some of the ink is pushed out of a nozzle onto the paper. When the bubble "pops," a vacuum is created, pulling more ink into the print nozzle from the cartridge. A typical bubble jet print head has 300 or 600 tiny nozzles and all of them can fire a droplet simultaneously.

b) The piezoelectric technology is patented by Epson. It is designed to work with piezo crystals. A crystal is located at the back of the ink reservoir of each nozzle. The crystal may be charged with a tiny electric current that causes it to vibrate. Then, the crystal vibrates inwards, forcing a minute amount of ink out of the nozzle and when it vibrates outwards, it pulls some more ink into the reservoir to replace the ink sprayed out.

3. Solid ink printers

These printers are also known as phase-change printers because of their thermal transfer processes. They use solid sticks of CMYK colored ink, which look like candle wax. The solid ink has to be melted and fed into a piezo crystal operated print-head in order to produce ink droplets. The print head sprays the ink on a rotating, oil coated drum. The sheets of paper then pass over the print drum and the image is transferred, or transfixed, to the page.

Solid ink printers prove to be highly efficient color solutions in office environments, and are excellent at printing on transparent media and other non-porous surfaces. Acquisition and operating costs are similar to laser printers, but there are some drawbacks, too. The solid ink printers are power-hungry solutions and they have long warm-up times from a cold state. This type of printer is only available from Xerox, as part of their Phaser office printer line. Previously, solid ink printers were manufactured by Tektronix, but this company sold the printing business to Xerox in 2000.

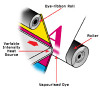

4. Dye-sublimation printers These are known as dye-subs for short. They employ a printing process that uses heat to transfer specially designed dyes to a medium such as a plastic card, paper or canvas. The dye-sublimation process consists of successive color passes using a ribbon that features separate color panels. Dye-sub printers are proficient at high-quality color applications, including color photography. Once this technology became more accessible to be implemented, dye-sublimation printers flooded towards consumer dedicated photo printer markets.

Dye-sublimation printing has an important advantage over Inkjet printers - the ability to print a superior range of colors. Dye-sublimation printers are able to change the temperature of the thermal elements in its head at 256 different degrees, therefore producing 256 different shades of each of the colored panels. More importantly, due to its properties, the dye is transparent and colors can be laid on top of each other, combining to produce 16.8 million different shades. The technology also features a final laminate coating which makes prints from a dye-sublimation devices look as if they have been developed from a photochemical lab. However, dye-sublimation printers also have some drawbacks over their inkjet rivals. Each of the colored panels of the ribbons, and the thermal head itself, match the size of the media that is being printed on. This means that dye-sublimation printers cannot match the flexibility of the inkjet printer's ability to print on a wide range of media. In addition, dye-sublimation printing media and ribbons are sensitive to skin oils, which affect the sublimation capacity, and must also be free of dust particles which can lead to small colored blobs appearing on the printed media. The current standard is to include special filters to reduce the likelihood of these incidents, but keep in mind that a speck of dust can only affect one print as it becomes attached to the print during the whole process.

5. Plotters The true origins of this kind of printers presented vector graphics printing device that connected to a computer. Plotters printed their output by moving a pen across the surface of a piece of paper. This means that plotters were restricted to line art, rather than raster graphics as with the other printing technologies. They could draw complex line art, including text, but did so comparatively slower because of the mechanical movement of the pens. Because of this, plotters were incapable of creating a solid region of color; instead, they could hatch an area by drawing a number of close, regular lines. They were mostly used in CAD applications, but with the emergence of faster and preciser laser and ink technologies, they became obsolete. Nowadays, the term plotter is informally attributed to large industrial inkjet or laser printers.

This concludes our brief look at printing technologies. Tommorow we will analyze the scanner, which transforms analog pictures into digtal ones.

14 DAY TRIAL //

14 DAY TRIAL //