In a paper published in the April 13 issue of the esteemed journal Physical Review Letters, scientists at the Nara Medical University, in Japan, led by expert Shigeyoshi Osaki, explain how they created a series of violin strings out of silk harvested from captive spiders.

Their efforts were focused on a material called dragline silk, which is the type spiders use to dangle as they construct their webs. The material, made from protein fibers that are extremely strong and stretchy, is used by orb-weaving spiders, too.

The research team used 300 captive Nephila maculata, a species of orb-weaving spiders, to collect sufficient dragline silk to create the strings. But the task of putting them together into an orderly structure was not that simple.

One of the things this material has going for it is the fact that it's stronger than steel, if similar volumes are compared. This resistance is what enables an entire orb-weaving spider – one of the largest arachnids in the world – to hold on using just one such dragline silk wire.

If sufficient filaments are somehow fashioned into a slender rope, experts believe, the object would be strong enough to hold up a fully-grown man. However, building such a rope would take a lot of silk.

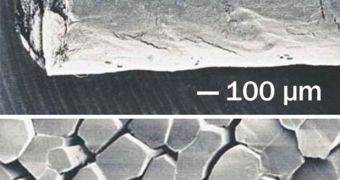

For the violin strings alone, Osaki had to use thousands of dragline strands, which the expert and his team painstakingly collected from their captive spiders. After creating small bundles out of these strands, the group treated them with a gelatin solution.

This enabled the dragline silk to become flat on its sides, rather than curved, as normal. “The most interesting aspect to this paper is the change in shape from round to polygonal when they wound the fibers,” investigator Randy Lewis explains.

He adds that no one ever managed to obtain polygonal spider silk until now. The expert holds an appointment as a molecular biologist and spider silk expert at the Utah State University, in Logan.

The silk strings the Japanese experts obtained were then installed on a Stradivarius violin, and a number of professional violin players asked to sing some of their favorite tunes with this instrument.

When it came to comparing the sounds with those produced by catgut or steel strings, players rated the spider silk strings above the others, saying it had a better sound, with stronger overtones.

While natural spider silk will forever remain a scarce resource, experts hope that genetic engineering will one day allow them to produce dragline silk by placing spider genes in other organisms, Science News reports.

14 DAY TRIAL //

14 DAY TRIAL //