Fire may have been the first major discovery of the prehistoric man, but the wheel was the first invention of any note. More so than cave murals and anything else achieved by the caveman.

To this day, the wheel continues to be an intrinsic part of human society and creation, in all its forms. There are normal wheels, there are sprockets, there are ball bearings, all of them just another type of wheel in the end.

Still, the word wheel is only used for those solid circles that support the weight of a vehicle or other and allow for easy travel across terrain or other surfaces.

Knowing the issues that may arise if one uses a less than optimal wheel type for specific terrains, Carter Hurd of The Ohio State University set about reinventing the wheel.

The 3D printed wheel

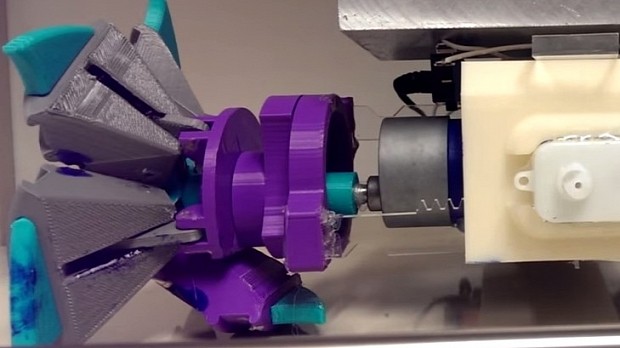

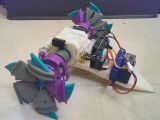

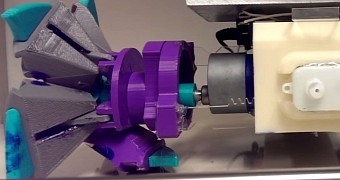

Hurd's latest invention is casually called the transforming wheel and is actually a robot accessory that allows robots to navigate any sort of terrain.

Well, maybe not every kind of terrain in the world, but still more than one type. That's ultimately all that's important at the end of the day.

The transforming wheel is the first 3D printed project from Hurd, making it all the more remarkable. It is very intricate even among the projects of 3D printing veterans.

His inspiration was an orange he was eating actually. It gave him the idea for the actuation plate. Normally, it would have been complicated and long-winded to create the resulting robot, but 3D printing saved him a lot of the hassle he usually went through when inventing things.

Quite telling really, that additive manufacturing took the normal way he worked and flipped it on its head. Where before it was most complicated to make the idea into reality, now it's just as easy as getting the idea itself, if perhaps less spontaneous.

The design of the new wheel

It's more simplistic than you'd expect, and it relies on interlocking sections. Every major part was printed on a MakerBot 2X printer, but you should be able to do the same on any other model.

All components can be printed without having to print support structures. It means you don't have to pick off all the loose ends at the conclusion of the print job.

The spikes are interchangeable (this is where much of the adherence customizability comes from). Arduino software controls the motors of the robotic wheel through an Adafruit shield, and a Bluetooth module receives inputs from you.

Indeed, one may as well call this wheel a robot made from multiple smaller wheels, most of which remain round while the robot is stored, but transform into spikes for outside use, where GPS positioning can help navigation when you're not directly guiding it.

14 DAY TRIAL //

14 DAY TRIAL //