Taiwan Semiconductor Manufacturing Company plans to woo Apple once again in 2016 by showing off a new manufacturing process to secure A10 orders for the iPhone 7.

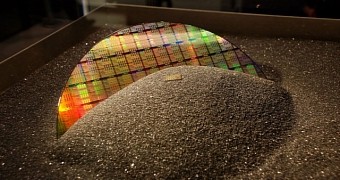

TSMC is on track to finish deploying its backend integrated fan-out (InFO) wafer-level packaging (WLP) technology for the manufacturing of 16nm A10 chips for Apple, according to industry sources in Taiwan.

TSMC has its sight set on Cupertino

Likely angered after losing the bulk of A9 orders to rival foundry Samsung, TSMC plans to flash its InFO-WLP technology before Apple’s eyes with plans to begin manufacturing A10 SoCs on a 16nm process in 2016. The sources said TSMC is also working to secure orders on an even smaller process (10nm) in 2017.

Regarded as a cheaper alternative to TSMC's existing CoWoS (chip on wafer on substrate) process, InFO-WLP packaging is still relatively high-priced compared to flip-chip chip-scale packaging (FC-CSP), according to integrated circuit makers cited by DigiTimes, which may or may not put off Apple.

Unfortunately, not much is being said about the actual benefits of using InFO-WLP packaging, but according to the Institute of Electrical and Electronics Engineers (IEEE), such technology would “dramatically improve performance and power consumption,” which is always high on the list of priorities for all kinds of chips, not just processors in general.

iPhone 7 release date

Historically, Apple has refreshed the designs of its iPhones once every two years. While there are rumors that the company might seek to break tradition this year – introducing the incrementally-updated iPhone 6S earlier to make room for the 7 in fall – there is little evidence to back these claims.

Furthermore, production on the A9 series of chips has barely even started (even that has yet to be confirmed), so for TSMC starting building a next-next-gen chip after failing to secure orders for the next-gen model would take more than a herculean feat.

14 DAY TRIAL //

14 DAY TRIAL //