The power efficiency currently exhibited by small manufacturing processes is not enough for some companies, so SuVolta decided to create a technology that can cut processor requirements in half.

SuVolta is an upstart company based in Silicon Valley and which invented the PowerShrink technology.

What PowerShrink does, or is supposed to do, is enable chips, like embedded memory or whatever else, to operate on 50% less power without losing performance.

For example, an embedded memory chip with a 1 Volt power requirement would run just fine at 0.425 volts.

SuVolta says that PowerShrink is suited for everything from SoCs (system-on-chip platforms) to other existing chip designs and circuits where energy conservation is important.

The Deeply Depleted Channel (DDC) technology is the main component of PowerShrink and has been adopted by Fujitsu for a demo product run.

“Since dynamic power is proportional to the square of supply voltage, power consumption has become a primary issue for CMOS technology,” the company says.

SuVolta did what it did because, even though process manufacturing technologies have gone from 130nm to 28nm, the power requirements never really changed from the aforementioned 1.0 Volt.

Truly ecological products will be invented now that this breakthrough was made, provided the initiative doesn't end up fading into obscurity like so many other ideas ended up doing over the years.

Fujitsu implemented the SuVolta DDC transistor on a low-power CMOS and intends to aggressively develop the technology over the next years.

Thus, there is not much danger for SuVolta's efforts to be in vain just yet.

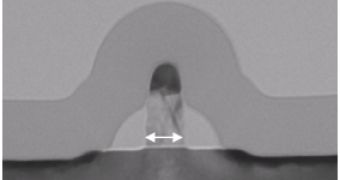

As for how it works, PowerShrink inserts dopants (elements that change the electric properties of a substance) into certain parts of a transistor.

With that to make the energy needs of individual transistors more consistent, the voltage requirements themselves become easier to predict, hence the reduced power waste.

14 DAY TRIAL //

14 DAY TRIAL //