Few people know that not all materials normally stick together, but many of you have had troubles sticking two surfaces together that no superglue seemed to be able to hold in place.

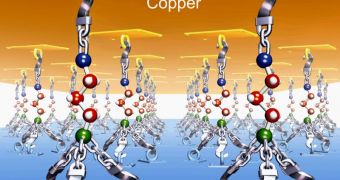

A new adhesive has been created, that nods with almost every type of surface on the nanoscale. It has been developed by the Rensselaer Polytechnic Institute and it's based on self-assembling nanoscale chains.

The nanoglue has a thickness of less than a nanometer, which is one billionth of a meter. Its production costs are very low, but the main advantage is the fact that unlike other adhesives, this one can withstand temperatures far higher than what was previously envisioned.

In fact, instead of breaking the molecular bonds, the heat acts as a strengthening agent, further increasing the adhesion level.

Engineering professor Ganapathiraman Ramanath and his team stumbled upon the new nanoglue by accident, as they were working on an already commercially available glue. They were searching for ways to assemble layers of molecular chains between two different materials to enhance the structural integrity, efficiency and reliability of semiconductor devices in computer chips.

They found that some molecular chains having a carbon backbone and ending with the right atoms, like silicon, oxygen or sulfur, can greatly improve the adhesion and even prevent heat from triggering the mixing of atoms of the glued surfaces.

They sandwiched a nanolayer between a thin film of copper and silica and discovered that this structure provided extra support that strengthened the bonds to improve the adhesive properties.

"The higher you heat it, the stronger the bonds are," Ramanath said. "When we first started out, I had not imagined the molecules behaving this way."

Applications of this new adhesive could be found in many scientific and industrial fields, from next-generation computer chip manufacturing to energy production and the fact that it can withstand high temperatures could make it extremely useful on hot surfaces, such as in holding paint on hot surfaces like the inside of a jet engine or a huge power plant turbine.

"This could be a versatile and inexpensive solution to connect any two materials that don't bond well with each other," Ramanath said. "Although the concept is not intuitive at first, it is simple, and could be implemented for a wide variety of potential commercial applications.

"The molecular glue is inexpensive - 100 grams cost about $35 - and already commercially available, which makes our method well-suited to today's marketplace. Our method can definitely be scaled up to meet the low-cost demands of a large manufacturer," he said.

14 DAY TRIAL //

14 DAY TRIAL //