Spansion, a company developing flash memory solutions, today announced that it has started production of NOR memories based on 300mm wafers and 65 nanometer fabrication process at its SP1 manufacturing plant in Japan. The company plans to attain full productivity levels by the end of the year while keeping pace with the increasing demand for flash memory products from its customers.

The Spansion 1, SP1 for short, flash memory manufacturing plant is the first and oldest factory constructed by the company since it became an independent body and it has invested almost $1.2 billion in order to construct and equip the said facility. According to the company, the SP1 plant is expected to reach a level of 15,000-20,000 300mm wafers per month and thanks to the future projected investments in production equipment and staff, the total output of that plant will go as high as 30,000-40,000 wafers per month.

Spansion plans to use the newly equipped facility to produce high end devices like those based on the MirrorBit Eclipse technology and 45 nanometer based products are expected to hit the market early next year. "We are on schedule for scaling MirrorBit technology to 45nm on 300mm wafers," said Bertrand Cambou, president and CEO, Spansion. "By leveraging this next-generation facility, and the cost and technology advantages of MirrorBit technology, we can deliver on our promise to bring more value to our customers and redefine the Flash memory industry."

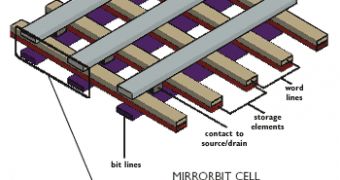

MirrorBit is a type of flash memory technology that offers higher yield rates than the more traditional floating gate NOR chips while being more easily scaled up to high density and storage capacity devices. This new technology is usually used in conjunction with the traditional floating gate NOR in order to produce a simpler memory cell design that will require fewer production steps before being ready to be integrated into an end product fit to market.

The SP1 production facility is located in Aizu, Japan and it is featuring a clean room with a total surface area of 13,800m2 and the company expects to be able to mass produce MirrorBit based flash memory chips starting in 2008.

14 DAY TRIAL //

14 DAY TRIAL //