Solid-state drives are becoming increasingly popular on the notebook market, as they are light, energy-efficient and extremely hard to destroy. The absence of moving parts makes solid-state drives the favorite pick if you need extended performance and durability.

However, the absence of moving parts does not mean that the chips inside it are not running hot. It's true that they are colder than average hard-disk drives, but they still warm up, which, in time, can result in solid-state drive failure. That's why a group of engineers at the Thorrn Micro Technologies have developed an innovative solid-state cooling device that promises to revolutionize the consumer electronics industry.

Dan Schlitz and Vishal Singhal are the two engineers that designed the RSD5 solid-state fan. According to Singhal, the fan is "one of the most significant advancements in electronics cooling since heat pipes. It could change the cooling paradigm for mobile electronics." The two engineers claim that the principle behind the fan is identical to that used in household air purifiers.

The tiny SSD fan is extremely powerful, and, in order to go well along with the solid-state drive itself, needs to be extremely energy-efficient. The engineers claim that it can move the same airflow as a regular fan that's 35 times larger.

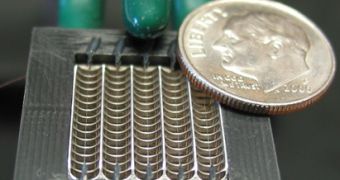

According to its inventors, the fan is operating using corona wind, a phenomenon created by the integration of a few wires within uncharged conducting plates in a semi-cylindric shape. The wires are able to generate plasma that is then crossed by electrical currents.

The generated wind is the result of ions pushing neutral molecules from the wire to the plate. "The technology is a breakthrough in the design and development of semiconductors as it brings an elegant and cost effective solution to the heating problems that have plagued the industry," said Juan Figueroa, the program officer.

The two researchers were able to control the plasma discharges without additional side-effects, such as microsparks or magnetic fields to interfere with the electronic components. Schlitz added that sub-1 cubic centimeter cooling system can ventilate a 25-watt chip and the technology might be scaled down to get integrated in the chip's silicon.

14 DAY TRIAL //

14 DAY TRIAL //