These days, the web seems to be focused on the consumer market as far as the IT industry goes, but this doesn't mean that other sorts of milestones are forgotten, one of the recent ones being a breakthrough in nanowire manufacture.

Nanowires are some of those technological elements that not many people know about but which play an integral part in many sorts of devices. The main two uses for them are in solar cells and batteries.

This is also the reason why researchers are constantly doing their best to improve on them, and while advancements are made pretty regularly, milestones are a bit trickier, although not for lack of trying.

Now, it is reported that a team of scientists from the Max Planck Institute for Intelligent Systems in Stuttgart (formerly the Max Planck Institute for Metals Research) came up with something interesting.

Specifically, they found a new method of mass producing nanowires on an industrial scale much more cheaply.

Anyone in the world will know that the past few years haven't been particularly kind in terms of finances.

While 2008 and 2009 were the most dismal for the IT industry, the effects from the recession haven't gone away yet.

As such, cost accessibility gained a higher importance than before, meaning that what the researchers, in this case, discovered could be a game changer.

The reason nanowires are hard to make is because they need expensive catalysts, like gold. They are also produced at very high temperatures (600-900 degrees C).

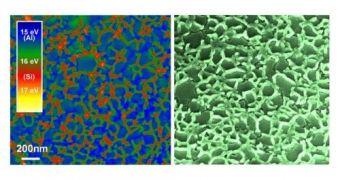

The milestone reached now makes it possible to produce crystalline semiconductor nanowires with cheaper material (aluminum instead of gold) and at temperatures of as low as 150 degrees Celsius.

Unfortunately, as is usually the case with projects of this sort, it is impossible to tell how long it will take for the technology to be practically implemented.

14 DAY TRIAL //

14 DAY TRIAL //