Harvesting solar energy is a clever way to make use of a clean and renewable fuel. You don't need to dig the ground for it, there are no pipes and powerplants, and best of all, it's ecological.

Unfortunately, existent solar cells are not too efficient and can't convert more than 10 percent of the solar energy into electricity of heat and they don't exactly come cheap, either.

A new technology could one day reduce the costs and increase the efficiency with the aid of a shampoo ingredient.

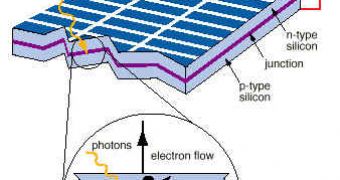

Normal panels are made with quantum dots, nanoscale semiconductors made of cadmium selenide, each smaller than a wavelength of visible light and capable of converting sunlight to electricity.

The best ones so far at converting light to power are called tetrapods, because each has four "legs" that seem to help electrons flow better.

However, there is now an efficient method of creating tetrapods in a uniform manner. Existing techniques can make a lot of tetrapods, but with crooked arms, missing arms and arms of uneven lengths, each of which vary in how efficient they are for solar power.

"Even in the best recipe, only about a third of all resulting particles are tetrapods", explained Rice University chemical engineer Michael Wong, who, together with his colleagues, created a new formula for successfully creating perfect tetrapods.

The new find now results in more than 90 percent tetrapods and the improvement is made using a shampoo ingredient.

It's a surprising approach, cheaper than conventional expensive compounds known as alkylphosphonic acids that alter the surfaces of quantum dots, interrupting their tendency of becoming spheres and forcing them to grow legs, thus forming tetrapods.

What they discovered is that a positively charged molecule with the strange name of cetyltrimethylammonium bromide produced a radical improvement in the tetrapod manufacturing process.

This chemical is common in some shampoos and it's about 100 times cheaper than the alkylphosphonic acids and much safer too.

The future applications of the new technique could lead to thin, flexible and more efficient solar panels, "doing things that more rigid silicon-based solar cells can't do," Wong said.

14 DAY TRIAL //

14 DAY TRIAL //