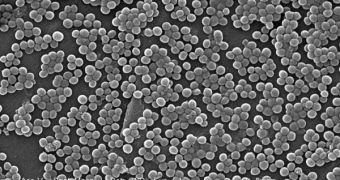

Given the increasing incidence of MRSA infections in US hospitals, over the past years scientists have been trying to create chemicals that would finally eradicate the resilient Methicillin-resistant Staphylococcus aureus (MRSA) bacteria, as well as other related microorganisms. They wreak havoc in hospitals, as they infect the very people that suffer from weak immune systems. The new substance, developed by experts at the Queen's University Belfast, comes as a fluid instead of a solid antibiotic, and appears to be able to completely kill the bacteria and also prevent them from reappearing.

When a surface becomes infected with MRSA, for example, it usually means that the bacterial colonies “glue” themselves to it and then cover themselves with a protective layer known as a biofilm. This barrier is hard enough in some species of bacteria to prevent anti-bacterial agents and antibiotics from breaking through and kill what lies underneath. This “shield” of sorts is especially strong in MRSA and other similar cultures, which makes killing them a top priority.

“We have shown that when pitted against the ionic liquids we developed and tested, biofilms offer little or no protection to MRSA, or to seven other infectious microorganisms,” the assistant director of the Queen's University Ionic Liquid Laboratories (QUILL) Research Center, Martyn Earle, explains. More details on how the new ionic fluids act on the microfilms have been published in a recent edition of the scientific journal Green Chemistry.

Ionic liquids are very similar to salts in their composition, and are essentially made up of electrically charged atoms, known as ions. The major difference between the new chemicals and the average salt is the fact that the latter has to be heated to as much as 800 degrees Celsius in order to become liquid, whereas the innovative fluids are able to maintain their mobile properties at room temperature. “Our goal is to design ionic liquids with the lowest possible toxicity to humans while wiping out colonies of bacteria that cause hospital acquired infections,” Earle adds.

“Ionic liquid based antibiofilm agents could potentially be used for a multitude of medical and industrial applications. For example, they could be used to improve infection control and reduce patient morbidity in hospitals and therefore lighten the financial burden to healthcare providers. They could also be harnessed to improve industrial productivity by reducing biofouling and microbial-induced corrosion of processing systems,” the Lecturer in Pharmaceutics at the School of Pharmacy, Brendan Gilmore, who has worked together with Earle for the new paper, concludes.

14 DAY TRIAL //

14 DAY TRIAL //