Researchers from NASA’s Jet Propulsion Laboratory, the California Institute of Technology, Pasadena, and Pennsylvania State University, University Park, have achieved a staggering breakthrough in the field of 3D printing: multi-metal printing within a single print.

Normally, to 3D print objects from metals you need to deposit metal or sinter a bed of metal powder, layer by layer, on a bed / build plate. However, the new method invented by the research team takes a different approach.

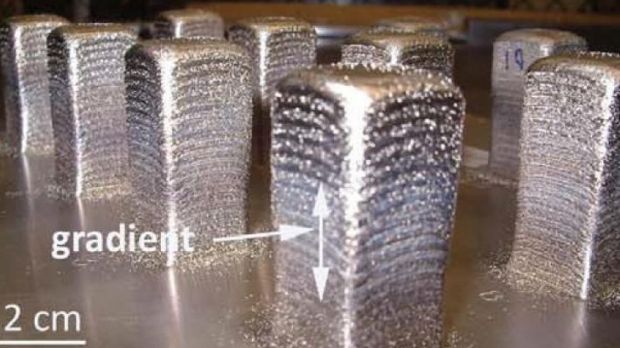

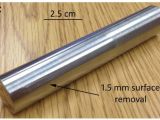

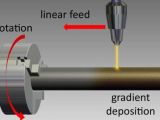

Here, the metal is sintered on a rotating rod instead, allowing the inside of a part to be made of a different alloy than whatever comes after, over it.

There are four powder blowers making up the head of the printer, which is an application not too dissimilar from the multi-extruder nozzles of some FDM plastic printers.

However, metal cannot just be superheated and layered like plastic can. Instead, the new printer had to use a laser to melt the four metals coming out of the 4 powder blowers, all the while not needing to change out the metal type.

There are many applications for this new technology, and studying the way different metal alloys mesh together is just the most basic of them.

For example, a jet part could be printed in a single run out of several different alloys, giving it new properties than can be bestowed upon it through conventional fabrication lines.

The area that, say, makes contact with a heat source could be made of a highly enduring substance, while the part on the other side could be optimized with a material that withstands extreme colds instead.

All the while, the jet part could be stronger, but also lighter due to being less dense. Future planes may reach far greater flight heights and be easier to transport as well. The same for tanks, train locomotives, cars, etc.

Moreover, 3D printed parts could be used to make better and cheaper, easier to maintain manufacturing lines as well. Because even though 3D printing can be used for manufacture, normal methods will still be used for bulk production of standard components. So if 3D printing can help improve them, why not? It's not a concern at present, but it could become one eventually.

Nevertheless, the main focus remains the creation of objects and parts of objects that combine several materials (and, thus, properties) without needing screws, bolts, or welding to stay in one piece.

14 DAY TRIAL //

14 DAY TRIAL //