There has been a 3D printer on the International Space Station for the past three months, and while it was only there as a trial for the technology, the Made in Space Zero-G has impressed pretty much everyone.

There was only one thing that hasn't yet been done: a planetside test of the objects 3D printed up there, off-planet.

While a bunch of objects, mostly tools and small plates, have been created just fine, they have yet to be subjected to the hazards of weight.

Now, it is finally happening. On Tuesday, February 10, 2015, SpaceX’s Dragon cargo spacecraft landed in the Pacific Ocean, about 259 miles / 416 km southwest of Long Beach, California.

3D printed samples produced on the Made in Space Zero-G Printer were among the thousands of pounds of cargo sent down from orbit.

The issues with 3D printing in space

It all boils down to gravity, or lack thereof. 3D printers are inherently reliant on the extra weight of solid matter compared to gas and fluids.

That means that an FDM printer is highly dependent on how superheated plastic will always drip downwards. SLA printers will depend on gravity to hold the resin down while light cures the prints.

And SLS printing would be nothing without gravity, since its disappearance would cause the powder to be spread all over the room when trying to add another layer.

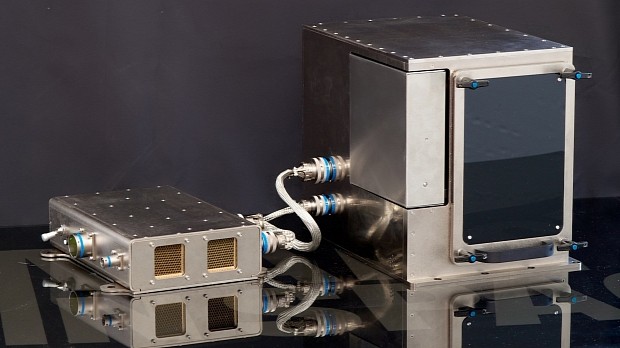

The Zero-G 3D printer uses FDM technology (fused deposition modeling) and had to be tested in a falling airplane before it was given the go to leave the planet.

Itself was made mostly out of metals and uses a sealed chamber, but also needed a fairly high precision in order to get away with relying on the cohesion force of plastic alone.

The return to earth

The samples didn't technically return, since they didn't exist before they were created up in space. If anything, they have made landfall. Extraterrestrial tools, if you can believe it.

Once they are shipped to Long Beach, they will be taken to the SpaceX test facility in McGregor, Texas, to see how they hold up.

Since they're just plastic, they should behave normally. It will be trickier in the future, when metal 3D printing is attempted. The mineral atoms might arrange in unusual patterns because of the zero gravity conditions.

14 DAY TRIAL //

14 DAY TRIAL //