German scientists at the Fraunhofer Institute for Photonic Microsystems IPMS have recently announced that they are working on a new, all-reflective zoom device. Designed especially for unmanned aerial vehicles (UAVs), the technology could make it possible to operate measuring equipment that is free of chromatic aberrations. Scientists have been trying to achieve this for quite some time now, and it would finally appear that the Fraunhofer team is on the right track, AlphaGalileo reports.

The primary reason why the new objective will be capable to produce nearly flawless images is the fact that it will employ deformable mirrors, which will allow it to compensate for changes in the terrain underneath. At this point, UAVs carry only a limited number of lenses, on account of the limited weight available on the aircraft. However, its instruments need to cover every wavelength from ultraviolet to near- and mid-infrared, and also have the ability to snap normal and wide-angle images. Currently, there is a trade-off when it comes to quality in wide-angle images, precisely because of the chromatic aberrations that appear in the cameras.

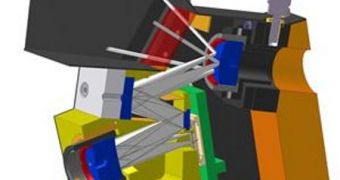

“We’ve come up with a design for a new objective in which we’ve used mirrors instead of standard lens elements,” IPMS group manager Dr. Heinrich Gruger explains. The single system, he goes on to say, covers a number of wavelengths, which in turn frees up more space for other components. Just four mirrors set the base for the new system, but their arrangement ensures that the need for complex mechanical systems in the barrel of the lens is eliminated. The method results in triple zoom that is achieved without a loss of quality, the German researchers say.

“For the zoom function, we need mirrors that will permit flexible actuator control of the radius of curvature,” the group manger adds. “Both the automation technology sector and the automobile and equipment engineering sector would profit from this type of objective,” he believes. The IPMS team was already able to demonstrate the new technology in three prototype devices, featuring lenses of various diameters, which were able to produce the results predicted in computer models.

14 DAY TRIAL //

14 DAY TRIAL //