The field of electronics along with a host of industry representatives and healthcare experts admit that nanoparticles are most likely the materials of the future. These small structures, measuring only billionths of a meter in size, can be used to deliver drugs, create more efficient electronics, and produce cotton that acts as a body armor. But one notorious problem experts have been having with these compounds is getting them to stick on a substrate. Recently, this issue was solved, AlphaGalileo reports.

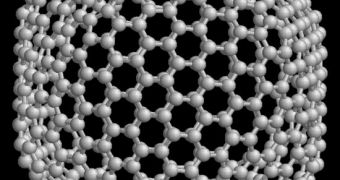

Researchers determined that by using a double layer of spherical C60 carbon-molecules, called fullerenes, they could provide a cushioning substrate for nanoparticles. The groundbreaking discovery is bound to promote the introduction of nanoparticles in our daily lives a lot faster than experts first estimated. Details of the substrates, produced by researchers at TU Dortmund, the University of Freiburg and the Fraunhofer Institute for Mechanics of Materials IWM, are presented in the current issue of the esteemed scientific publication Nature Nanotechnology.

One of the most important applications that derive from this innovation directly is making nanosystems a tangible reality. As technology decreases in size, a host of various physical and chemical effects begin affecting matter. At high levels of miniaturization, experts need to use specials materials to create structures, and most often they begin from bottom to top. In other words, they do not miniaturize existing objects, but rather construct them molecule by molecules. This is where nanoparticles come in, and the fact that they can now be fixed to substrates is of paramount importance.

The German research team showed that using two layers of fullerenes was much more efficient in maintaining the integrity of the nanoparticles than using a single layer. They say that by adding an extra amount of fullerenes, they were able to maintain various types of particles stable for a few days, even at room temperature. Generally, these are considered to be very warm conditions for nanoparticles, which are usually kept cool. However, when a single layer was used, the particles became rather instable, and were therefore lost within only a few hours. In the double-layer setup, traits such as size and shape remained unchanged, an ability that is essential for industrial applications.

14 DAY TRIAL //

14 DAY TRIAL //