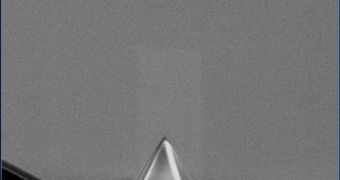

A group of researchers has recently announced the development of a new type of nanoscale tip that represents a significant improvement from existing technologies. The new structure, which is shaped like a tip, has a massive resistance to wear, and is far more suitable for a wide range of applications than its silicon-based counterparts, which are currently the norm. Scientists from the University of Pennsylvania (UP), the University of Wisconsin-Madison (UWM) and IBM Research-Zurich collaborated for this innovation, e! Science News reports.

The carbon tip is extremely sharp, and closely resembles a diamond. It is extremely strong, researchers say, as it turns out that it wears at a rate of about one atom per micrometer, when dragged across a substrate of silicon dioxide. This makes it about 3,000 times more resistant than silicon, and opens the way for applications in atomic force microscopy (AFM), nanolithography, nanometrology, and nanomanufacturing, as well as in replacing silicon microcantilevers in most applications where this technology is currently used. The innovative structure is constructed entirely out of only four chemical elements – carbon, hydrogen, silicon and oxygen, the team says.

One of the most important aspects of the new development is the fact that it proved to be so resistant to wear when faced with silicon dioxide, which is a very strong substrate. In modern electronic devices that feature integrated circuits, silicon oxidizes in the presence of air to form a thin layer of oxide on its own surface. This hinders a wide variety of processes, especially in many fields of nanotechnology, including the ones mentioned above. Having the ability to create microcantilevers that do not break when faced with this rough substrate could enable a large number of innovations that have been placed on hold until now, until new technologies would develop.

Another important thing that merits mentioning is the fact that the research group developed this new structure from scratch. Other teams tried to coat existing nanoscale tips with various types of wear-resistant materials, but these approaches produced mixed results. The collaboration that came up with the new construction process says that it has already developed the necessary technological requirements to scale up its production process, which means that sufficient amounts of the new tips could be produced for wide-scale industrial use.

14 DAY TRIAL //

14 DAY TRIAL //