Scientists from the Technische Universitaet Muenchen, in Germany, announce the development of a new type of diesel engine, which not only emits only trace amounts of dangerous chemicals, but can also be used to collect samples from the combustion chamber while the engine is still running. The newly developed diesel engine seems capable of meeting the proposed EURO 6 pollution norms for all types of vehicles. It appeared just a few months after the latest set of European regulations (EURO 5) went into force for all new cars.

The new EURO 6 norm is scheduled to be implemented in 2014, regulators say. It will contain very drastic restrictions to particle emission from burning fossil fuels. In the case of a diesel engine, plans are to impose a limit of five milligrams of soot particles and 80 milligrams of nitrogen oxides per kilometer. For comparison, the EURO 5 norm permits twice as much nitrogen-oxide emissions, while EURO 4 (which was the main norm until this August), allowed for four times more oxide to be emitted.

The goal of the TUM research team was to develop a fully fledged diesel motor that not only complied with EURO 6, but also did so without resorting to a catalytic converter. The German research group was led by Professor Georg Wachtmeister, who holds an appointment in the Chair of Internal Combustion Engines at the University. The engine was developed under the NEMo (Niedrigst-Emissions-LKW-Dieselmotor) project, which stands for “lowest emission truck diesel engine.”

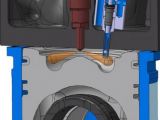

In the new engines, diesel fuel is pumped via special injectors, which have the ability to atomize the diesel into microscopic droplets, allowing it to burn up completely. This is a major problem in other engines, whose injectors put large droplets of fuel inside the combustion chamber. The droplets do not burn entirely, leading to more soot formation. The TUM team likens this to an onion. Its layers may fall off, or in this case burn, but the entire onion endures. It's the same with diesel. At one point, the droplets get so clogged with exhaust fumes, that there is no way for oxygen to reach and burn them.

A new sampling chamber has also been installed in the engine. This allows the team to collect samples from inside the combustion chamber while the engine is running, something that few scientists have attempted to do before. The chamber also allows them to keep an eye on what happens to the fuel as it burns. The group wants to analyze precisely how soot is formed in the split seconds after the fuel is injected. The experts say that the sampling instrument may help them accomplish that.

14 DAY TRIAL //

14 DAY TRIAL //