At this time, indium tin oxide (ITO) transparent electrodes are widely used for the creation of electronics such as liquid crystal displays, but a team of researchers has just developed a way of replacing the chemical with a combination of nanomaterials including silver nanowires.

The reason why ITO needs to be replaced is that a constant demand of a relatively scarce material – indium – is causing prices to increase constantly. This in turn drives the costs of the electronics themselves to rise even further.

What investigators at the University of California in Los Angeles (UCLA) wanted to do was develop an alternative to ITO that did not require indium, and to circumvent some of the drawbacks using indium tin oxide in electronics has today.

Some of these flaws include brittleness and unavailability. ITO cannot be used for flexible displays, for example, since the chemical cannot be stretched and bent without breaking. This limits its uses for next-generation electronics, scientists say.

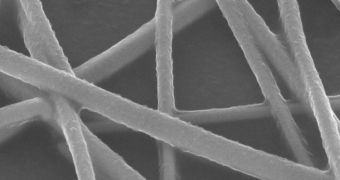

But UCLA scientists believe that these obstacles can be overcome by using silver nanowires, in combination with a host of other nanomaterials. The tiny wires developed at the university are very efficient inside electronics, and – furthermore – can be bent and stretched without breaking.

Details of the new material appear in the latest issue of the esteemed scientific journal ACS Nano. In the paper, the team details an innovative manufacturing process they created for the production of silver nanowire-based transparent electrodes that are both conductive and flexible.

“In this work, we demonstrate a simple and effective solution method to achieve highly conductive AgNW composite films with excellent optical transparency and mechanical properties,” explains UCLA research scientist Yang Yang.

“This is by far the best solution: a processed, transparent electrode that is compatible with a wide variety of substrate choices,” adds the expert, who is the director of the UCLA California NanoSystems Institute (CNSI) Nano Renewable Energy Center (NREC).

He conducted the work with colleague Paul Weiss, a professor of materials science and engineering and of chemistry and biochemistry at UCLA, and the director of the CNSI. Yang is himself a professor of materials science and engineering at the university.

The researchers were able to conduct this work thanks to funds provided by the Office of Naval Research and the Kavli Foundation. The study may also have applications in improving solar cell design, the research team concludes.

14 DAY TRIAL //

14 DAY TRIAL //