Carbon nanotubes have been considered for some time now the perfect building blocks for the future generation of ultrafast computers, but working with such small structures is no easy task, especially while trying to line them up into a specific architecture. This wouldn't be so big a deal, however it disables the possibility of mass production.

Some reoriented their research towards spintronics and other nanoscale materials in the hope that they would escape from the problems posed by the carbon nanotubes, while others, such as the researchers from Seoul National Universe in South Korea, developed ways to enable an auto-arranging technique. Kahp Suh has recently succeeded in creating a method through which carbon nanotubes inside a nanotube-containing solution align themselves on the basis of the flow of the carrier solution.

Considering the fact that the method does not require the input of any external stimuli, such as electric or magnetic fields, this could prove an excellent solution of carbon nanotube chip mass production. The team reports that the fluid carries the carbon nanotubes through a nanochannel, made out of a charged polymeric mold, where they fall into place in concordance with the capillary forces acting on them.

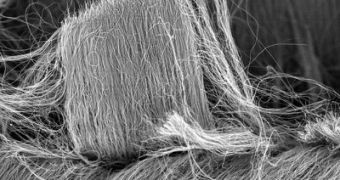

If the mold has the correct geometric design, then aqueous solutions carrying the carbon nanotubes may flow over its surface in non-preferential patterns, deposit the nanotubes to form a highly compact structure as the fluid component of the mix evaporates. However, the different properties of the polymeric mold bears great importance in the process fabrication of the carbon nanotube chips.

For example, the polymer has to have the correct rigidity; if too stiff, the carbon nanotube structure will not be able to bond well while setting on the mold, too flexible and the structure may collapse while extracted. Furthermore, the polymer mold needs to have good adhesion properties to prevent carbon nanotubes set in place from becoming loose and carried away by the flowing fluid.

While testing with multiple polymers, the researchers observed that the perfect mold needed to carry the task would be a polyethylene glycol diacrylate solution, which implies all the right properties. Glycol diacrylate solutions also have great affinity towards water, meaning that the carrier fluid would enter through each channel of the mold without requiring additional interference.

14 DAY TRIAL //

14 DAY TRIAL //