New generations of nanomaterials could be used to harvest more energy out of the wasted heat many electrical devices and industrial processes create. Rensselaer Polytechnic Institute (RPI) scientists have recently developed such a material, which they say works in a very efficient manner.

Waste heat appears wherever there are electrical circuits. Due to the fact that these electrical conduits oppose resistance to the passing of electrons, various amounts of the elementary particles are released as heat from the cables. As a rule, less efficient circuits heat up faster.

Until science comes up with a way of creating all electric circuits from superconducting materials, experts will have to make do with recapture and recycle technologies. The goal here is to capture as much as possible of the wasted heat, and return it to the circuits as electricity.

New heat-harvesting devices based on the approach developed by RPI engineering researchers should be relatively straightforward to construct. All that is needed to create the new nanomaterial is aluminum and a standard microwave oven.

One of the key ingredients in any heat-harvesting device is for it to be built out of a material can let electricity pass throughout as efficiently as possible, while failing to conduct heat in the same manner.

Zinc oxide has thus far proven itself to be the most relevant candidate for such applications. The nontoxic material is inexpensive to obtain, and has a very high melting point. However, zinc oxide has a high level of thermal conductivity.

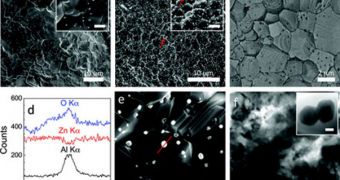

Given that this was an obstacle in its ability to collect and convert waste heat, RPI investigators had to destroy this conductivity. They managed to achieve this objective by adding minute amounts of aluminum to the zinc oxide, and then processing the mixture in a microwave oven.

The work was led by RPI Materials Science and Engineering Department professor Ganpati Ramanath. His team worked closely with colleagues at the University of Wollongong, in Australia, for this study.

“Harvesting waste heat is a very attractive proposition, since we can convert the heat into electricity and use it to power devices – like in a car or a jet – that is creating the heat in the first place,” the team leader explains.

“This would lead to greater efficiency in nearly everything we do and, ultimately, reduce our dependence on fossil fuels,” Ramanath adds. A paper detailing the findings appears in a recent issue of the scientific journal Nano Letters.

“We are the first to demonstrate such favorable thermoelectric properties in bulk-sized high-temperature materials, and we feel that our discovery will pave the way to new power harvesting devices from waste heat,” the RPI professor concludes.

14 DAY TRIAL //

14 DAY TRIAL //