Washington University in St. Louis (WUSL) investigators announce the development of a new microscale laser, no larger than a pinprick, which is capable of detecting and counting particles at the nanoscale with tremendous precision. Among the most important applications that researchers envision for their new device, they include monitoring particles that lead to the formation of clouds or to the thickening of pollution, and also counting individual viruses, bacteria and other microorganisms in the human body.

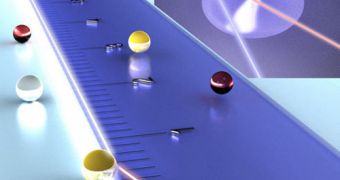

The minuscule laser is donut-shaped, and it represent the latest advancement in the field of silicon micro-miniaturization. The WUSL team says that detecting particles such as soot, viruses and salt is extremely important, given the huge role that these elements play in our daily lives.

This laser sensors is part of a family of electronics called whispering gallery resonators, whose main trait is the fact that they have resonances (sweet spots) at light frequencies. The same principles apply to acoustic constructions as well, where the sounds resonate in the audible range of humans.

Experts explain that the frequency of light traveling round the micro-laser is changed every time a nanoparticle lands on the ring. Whenever the electronic components of the laser detect such distortions, they make a count.

Each laser can detect up to 800 nanoparticles simultaneously. Beyond that number, the background noise becomes too powerful to conduct correct measurements. Interestingly, the WUSL team has also set up a method of double-checking the results.

Additionally, the laser ring could soon be adapted to working underwater as well, rather than exclusively in the air. This can be done by changing the gain medium on which the light pulses rely.

The research team that created the laser was led by WUSL assistant professor of electrical and systems engineering Lan Yang, PhD, who is also the lead author of a new paper detailing the findings. The work appears in the June 26 online issue of the top journal Nature Nanotechnology.

“The tiny sensors are mass produced by sol-gel method on silicon wafer, and it is easy to switch the gain medium,” explains WUSL graduate student Lina He, the first author of the study paper.

“The resonators are made by mixing the rare-earth ions of choice into a solution of tetraethoxysilane, water and hydrochloric acid. The solution is heated until it becomes viscous and then spin-coated on a silicon wafer and annealed to remove solvents and complete the transition to amorphous glass,” she adds.

“The thin film of glass is then etched to create silica disks supported underneath by silicon pillars. As a final step, the rough silica disks are reflowed into smooth toroids by laser annealing,” the student says.

14 DAY TRIAL //

14 DAY TRIAL //