University of Florida (UF) researchers have managed to devise a new way of bettering the existing microfluidic device technology, via the use of natural motor proteins, which are small molecules inside our cells that assist in the process of cellular division. Henry Hess, the engineering research team leader, has announced that the group is currently working on ways to make these small proteins even more efficient, so that they could take on the task that was previously accomplished by repetitive water cleansing, which required a lot of power.

“Instead of just changing one part of an existing system, we have a new and different way of doing things. And we can do it this way because of building blocks from bio-nanotechnology, and that's what makes it very exciting,” Hess, who is also an assistant professor of materials science and engineering at UF, as well as the senior author of a new paper, says, detailing the team's progress, which was published on Sunday in the Nature Nanotechnology journal.

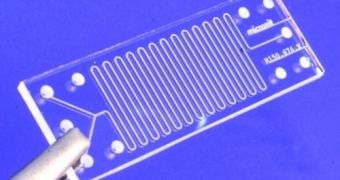

Regular microfluidic, or lab-on-a-chip, devices bind chemical analyzers with substances via the use of antibodies, but this technique requires a lot of work, in that the chip needs to be often cleansed with water. This makes it unfit to be used in the poorest regions of the world, such as, for example, Africa, where such devices are most needed to analyze the quality of water supplies and to prevent bacteria, viruses, or even epidemics from spreading.

The new system is based on another approach – instead of using the power of water, the antibodies are moved by the natural motor proteins, which do not require outside power sources. They operate on ATP (adenosine triphosphate), the substance that carries the energy inside our bodies. Thus far, the process has taken a couple of hours to produce results, but Hess says that further innovation will make the whole thing go a whole lot faster.

“Right now, this is light years away from competing with any assay. But, it is a completely different way of doing it,” Hess explains. The main goal of this line of research is to create devices so small and good at getting the job done, that they could be organized in the form of a “smart dust cloud” to be sprinkled on top of a suspect substance and produce analysis results within a matter of minutes or seconds.

Hess envisions a color-marker system, in which the cloud, gray at first, could be sprayed over a container, and quickly and visibly change color if a dangerous chemical is inside. This could give authorities a good head start in evacuating people from a particular area, and could potentially save lives.

“The key advance is that the authors incorporate a transport mechanism derived from a natural system into an artificial microsensor. The authors show how adding the ability to move around in an autonomous fashion can dramatically improve the performance of the microsensor,” University of California in San Diego chemistry and biochemistry professor Michael Sailor concludes.

14 DAY TRIAL //

14 DAY TRIAL //