Nature has found complex models long before humans discovered them and most of them are more effective than the human ones.

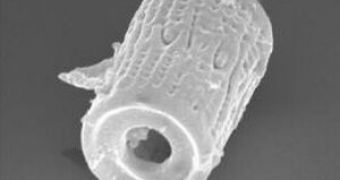

The three-dimensional shells of tiny ocean algae, called diatoms, could offer the foundation for novel electronics, like gas sensor devices that could be faster and more efficient than conventional devices.

A chemical process replaces the shells' original silica (silicon dioxide, SiO2) into the semiconductor silicon, in a unique and intricate nanoscale three-dimensional (3-D) shell model. The silicon shell, achieved after a seven-year research, could also be employed as battery electrodes, chemical purifiers and in other applications where complex shapes are necessary and which nature can produce better than humans can. "When we conducted measurements for the detection of nitric oxide, a common pollutant, our single diatom-derived silicon sensor possessed a combination of speed, sensitivity, and low voltage operation that exceeded conventional sensors," said Kenneth H. Sandhage, a professor in the School of Materials Science and Engineering at the Georgia Institute of Technology.

"The unique diatom-derived shape, high surface area and nanoporous, nanocrystalline silicon material all contributed towards such attractive gas sensing characteristics."

There are about 100,000 species of diatoms, and each species has a microshell with a unique and often complex 3-D shape, from cylinders to wheels, fans, donuts, circles and stars.

The researchers would like to get genetically-modified diatoms that synthesize microshells with tailored shapes. However, to precisely alter and control the structures produced, further research is needed to learn how to manipulate the genome of the diatom.

Diatoms are easily cultivable in large volumes, and genetically engineered diatoms would allow mass-production of complex and tailored microscopic shells. "Diatoms are fabulous for making very precise shapes, and making the same shape over and over again by a reproduction process that, under the proper growth conditions, yields microshells at a geometrically-increasing rate," said Sandhage.

"Diatoms can produce three-dimensional structures that are not easy to produce using conventional silicon-based processes. The potential here is for making enormous numbers of complicated 3-D shapes and tailoring the shapes genetically, followed by chemical modification as we have conducted to convert the shells into functional materials such as silicon."

Silicon is normally got from silica at temperatures over 1,414o C (the silicon melting point), when it cannot remain in the pattern of the silica shell.

So the team employed a reaction with magnesium gas that turned the silica of the shells into a composite containing silicon (Si) and magnesium oxide (MgO), at only 650 degrees Celsius, fact that allowed preservation of the complex shell patterns.

The magnesium oxide (about two-thirds of the composite) was then washed away by a hydrochloric acid solution, leaving a highly porous silicon structure and keeping the original shape. Traces of silica created by reaction with the water in the hydrochloric acid solution were removed with hydrofluoric acid (HF)

The individual silicon structures were connected to electrodes, and when charged with current were employed in detecting nitric oxide.

The silicon shells, roughly 10 micrometers in length, could also be employed to catch enzymes for purifying drugs in high-performance liquid chromatography (HPLC) and as better electrodes in lithium-ion batteries.

"Silicon can form compounds that have a high lithium content. Because diatom-derived silicon structures have a high surface area and are thin walled and highly porous, the rate at which you can get lithium ions into and out of such silicon structures can be high. For a given battery size, you could store more power, use it more rapidly or recharge the battery faster by using such structures as electrodes." said Sandhage.

The team found that this silicon was photoluminescent: it glows when illuminated by certain wavelengths of light, thus it may have photonic applications.

The new sensors must be packaged into useful arrays of devices scaled up for volume manufacture. "We can target diatoms of a certain shape, generate the right chemistry, and then work with applications engineers to get these unique structures into practice. We are now at the point where we have a good idea of the chemical palette that is accessible with the conversion approaches we have taken. The next step is really to start making packaged devices", said Sandhage.

14 DAY TRIAL //

14 DAY TRIAL //