Scientists at the Massachusetts Institute of Technology (MIT), in Cambridge, have recently developed a new method for producing tiny polymer particles. Unlike other approaches, the new one enables the creation of particles of any shape.

These particles are absolutely essential for the creation of new drug delivery system and artificial tissues, but their uses are severely limited by the fact that they can only be fashioned in a limited array of shapes, using very specific materials.

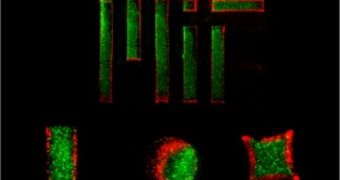

In the new study, the MIT team circumvented this limitation, by using a micromold that responds to temperature for creating microparticles of all shapes. The approach could eliminate the gap that has been blocking advances in this field for a long time.

At the same time, using this approach enables the team to create pockets inside the microparticles, which can be filled with a variety of drugs. When inside the body, this compartmentalization enables the steady, gradual release of drugs for long-term therapies.

In reconstructive biology, this property may be used to arrange cells in layouts that are identical to the ones of the tissues they are replacing. Details of the method appear in the July 18 online issue of the renowned Journal of the American Chemical Society (JACS).

According to MIT graduate student in electrical engineering and computer science Halil Tekin – also the lead author of the paper – the approach also enables experts to produce microparticles from a wider array of base materials, which may further expand their uses.

The investigation was led by MIT-Harvard Division of Health Sciences and Technology associate professor Ali Khademhosseini and David H. Koch Institute Professor Robert Langer. The team first selected materials to construct the micromolds.

They selected a series of materials that shrink under intense temperature, and then loaded the molds with a gel containing a single type of cell or drug. Once the gel solidifies, the molds are exposed to high temperature, and their walls shrink.

As this happens, extra room for an additional layer is created. At this point, the method only enables the creation of two layers, but the MIT team says that it may be possible to construct additional ones too.

“The method is quite creative. It offers the opportunity to make multilayer microstructures. The next step is figuring out what you can do with these two-layer structures,” says researcher Michael Sefton, who was not a part of the new investigation.

He holds an appointment as a professor at the University of Toronto Institute of Biomaterials and Biomedical Engineering.

14 DAY TRIAL //

14 DAY TRIAL //