Since carbon nanotubes (CNT) were first created, experts have realized that their future applications are in areas beyond electronics as well, including in designing, for example, cables to hold a space elevator. Among development leaders in this technology is Rice University professor and chemist Bob Hauge, who is taking single-walled carbon nanotubes (SWNT) production methods and end-products to new heights. He has recently managed to create carpet- and kite-like structures, all entirely out of SWNT. The expert holds an appointment in the RU Richard E. Smalley Institute for Nanoscale Science and Technology.

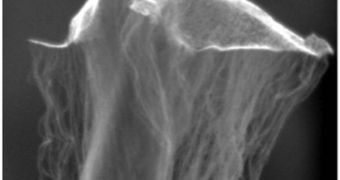

In their newest research, which appears in the latest issue of the respected journal Nano Research, Hauge and his team – including graduate students Cary Pint and Noe Alvarez – describe a method for creating “odako” bundles of nanotubes, formations that closely resemble the traditional Japanese kites, for which reason they are thus named. The experts reveal that the new process could allow scientists to create even meter-long strands of carbon nanotubes in time. This type of structures is very difficult to produce, considering that the tubes themselves are no wider than a DNA fragment.

The traditional Japanese kites are very complex to master, and are almost never flown by a single individual. As a result, when they fly, they have numerous Tails and wires attached to them. In the structures created at Rice, the wires are in fact carbon nanotubes, which are thousands of times smaller than living cells. However, the main accomplishment that Hauge made was to create SWNT bundles that were a few centimeters in size. He believes that, if the new process can create such long tubes, then it could, with refinement, be able to produce nanotubes of any length.

“If we could get these growing so they never stop – so that, at some point, you pull one end out of the furnace while the other end is still inside growing – then you should be able to grow meter-long material and start weaving,” the expert explains. The new structures he created resemble kites because the iron and aluminum oxide particles that are placed in the growth chamber are simply lifted in a sea of hydrogen and acetylene when the tubes are growing. At this point, all that researchers have to do is find a catalyst for the growth reaction that will not be consumed, and that will create continuous flows for SWNT.

14 DAY TRIAL //

14 DAY TRIAL //