Light emitting diodes, or LEDs, are amongst the most efficient light sources ever developed. In terms of energy efficiency, light emitting diodes are capable of producing the optical output of an incandescent light bulb, by consuming one hundred times less energy. The problem is that LEDs can't compete with incandescent light bulbs when it comes to high light outputs.

One way to correct this at relatively low costs would be to concentrate the light generated by the LED exactly on the spot where it is needed, leaving everything else in complete darkness. An optical system recently developed by the Fraunhofer Institute does exactly that.

"A light emitting diode is a single point light source that emits light in a large, uncontrolled area. We use special lenses to direct all of the light to the place where it is needed, thus increasing the efficiency of the LEDs. The spot of light created by the light source does not therefore fade out at the edges, but has a sharply defined edge", says Dr Christian Wenzel from the Fraunhofer Institute for Production Technology IPT.

Light is passed through a series of optic systems, containing a plastic lens that can be shaped in any way. "The lenses are cast using an injection-molding technique. The two halves of the tools that serve as the mold have to be aligned with extreme precision just once - they have an accuracy of a few microns, or less than a tenth of the diameter of a hair. Once the tools have been tared, the lens can be manufactured in large batches at low cost", Dr Wenzel explains.

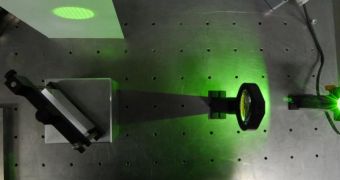

Because plastic shrinks as it cools, it comes off from the mold slightly smaller than designed. To master the fabrication process, researchers have to repeat the experiments until micron accuracy is obtained. The measurement of the lenses usually requires a technique involving the projection of a pattern of strips on the lenses. Any distortions in the pattern can reveal the exact curvature, inclination and shape of the manufactured lens.

14 DAY TRIAL //

14 DAY TRIAL //