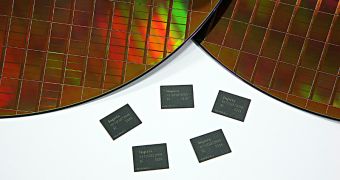

It appears that, at least so far, the disaster that struck Japan in the month of March hasn't had too great an effect on the semiconductor industry, although disruptions may still emerge in the short to mid-term.

The natural disaster that hit Japan on March 11 will always be remembered because of the immense death toll and the fact that it led to a nuclear meltdown.

Meanwhile, the rest of the world was found faced with issues on many levels of the economy, and the IT industry was definitely not spared.

In fact, given Japan's large stake in the technological industry, one might say things had the potential of being far worse than they ended up.

Ironically enough, the semiconductor segment managed to get off easy, even though factories were damaged or at least had their activities disrupted.

Prior to the earthquake and tsunami, chip makers and supplier were having somewhat serious oversupply issues.

It was those very same large inventories that enabled the global semiconductor industry to pass through the first quarter without as large a component shortage as it otherwise would have.

“Efforts by suppliers to build inventory during the seasonally slow period from the fourth quarter of 2010 through the first quarter of 2011 proved to be fortuitous,” said Sharon Stiefel, analyst for semiconductor market intelligence at IHS.

“These efforts resulted in a two- to-four-week cushion of raw materials, work-in-process goods and finished products, which came in handy when chip supplies were disrupted by the Japan disaster. While a large inventory overhang can be a negative development for the semiconductor industry—fueling excess supply, dampening pricing and reducing profits—it turned out to be a positive factor during the first quarter as the overall industry contended with supply shortages.”

The second quarter might also get off easy, although it is hard to say what will come afterwards.

14 DAY TRIAL //

14 DAY TRIAL //