As one would expect, the massive natural disaster in Japan is proving to have far-reaching consequences, not just in terms of casualties but also as far as the world economy goes, in this case the semiconductor market.

No doubt people around the world have already heard of the massive earthquake that struck Japan a few days ago and caused tsunamis to sweep in an engulf huge areas in killer waters.

Currently, the catastrophe is estimated to have caused about 10,000 deaths (or will cause because of how many people are stranded and without food or water).

The other major issue is the threat of nuclear meltdown and explosions that rocked the Fukushima Dai-ichi nuclear plant (the situation is still quite serious in fact).

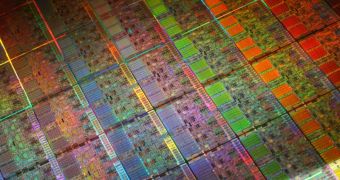

Meanwhile, the IT industry is coping with its own share of problems, that being disruptions to product supply chain, particularly silicon wafers.

It was reported that supplier Shin-Etsu Handotai (SEH) was affected by the disaster and that TSMC (Taiwan Semiconductor Manufacturing Company) and UMC (United Microelectronics Corp) are preparing to make up for it, so as to maintain the global supply stable.

To be more specific, some production sites, like SEH's Shirakawa plant in Nishigo Village, are shut down because of the power outage and won't be restarted until a safety inspection, whose length of time is unclear.

Either way, the general fear is that 12-inch wafers may end up in short supply, even with UMC's and TSMC's efforts.

Fortunately, UMC doesn't expect to be affected overmuch, as it gets its supplies from multiple sources, like MEMC, Siltronic, SEH and Sumco.

What's more, TSMC's supply partners in Japan seem to have made it out relatively unscathed, enabling wafer levels to stay sufficient.

All in all, the damage to the wafer industry could have been worse, although shortages are still a possibility.

14 DAY TRIAL //

14 DAY TRIAL //