Experts at the NASA Goddard Space Flight Center (GSFC), in Greenbelt, Maryland, announce the completion of a critically-important component of its next-generation flagship observatory, the James Webb Space Telescope (JWST).

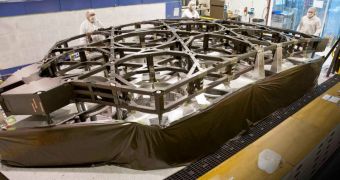

Engineers have just finished assembling the primary mirror backplane support structure, which is the center section of the backplane structure. The latter is one of the most important components on the telescope. The new achievement marks a milestone in the development of the JWST.

In addition to supporting the telescope's main beryllium mirrors, the support structure will also connect to thermal control system, some of the scientific instruments, as well as other hardware components.

Due to its importance for the mission, the center section was the first of three backplane pieces to be constructed. Its primary function will be to hold JWST' 6.4-meter (21-foot), 18-segment main mirrors still as the observatory flies through space.

Developing the center section was one of the most complex tasks in the entire project, since it needed to abide by some extremely rigorous specifications. The thermal stability requirements for this component are more stringent than those of any telescope built to date.

The structure itself is about 7.3 by 3.6 meters (24 by 12 feet), but it weighs less than 227 kilograms. A large number of new materials and manufacturing technologies were used for the JWST, in order to keep its weight down. It will be the largest and most complex telescope ever deployed to space.

The support structure will need to withstand the harsh vibrations of launch, and then endure massive temperature swings. It will sometimes be exposed to temperatures as low as minus 243 degrees Celsius (-406ºF), all while maintaining the telescope's main mirror perfectly aligned.

“Completing the center section of the backplane is an important step in completing the sophisticated telescope structure. This fabrication success is the result of innovative engineering dating back to the technology demonstration phase of the program,” explains Lee Feinberg.

He holds an appointment as the GSFC JWST optical telescope element manager. The scientist explains that the primary mirror backplane support structure is what enables the 18 hexagonal segments making up the main mirror to form a single, pristine shape.

This component was constructed by main contractor Northrop Grumman Corporation, in Redondo Beach, California. The company worked with subcontractor ATK, in Magna, Utah, on this project. The center section contains 1,781 parts, each made of graphite, using advanced manufacturing technologies.

14 DAY TRIAL //

14 DAY TRIAL //