Even though 25nm NAND Flash is just beginning to make its appearance in solid state disks, Intel and Micron have announced that they have begun sampling NAND Flash chips built using the 20nm fabrication process, which should enable SSD makers to deliver even cheaper drives.

The first 20nm NAND Flash is built at an IMFT manufacturing facility located in Lehi, Utah, which also builds 25nm NAND, but the two companies also want to convert other fabs located in Manassas, VA and Singapore to 20nm at a later point.

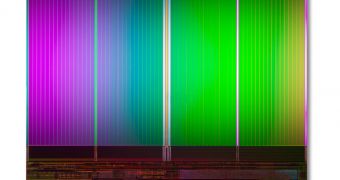

A 8GB NAND Flash device built at 20nm is about 30% smaller than a similar 25nm chip (118mm2 vs 167mm2) and it should be good for just as many program/erase cycles as 25nm NAND.

Drives manufactured using this new technology should be about 20 to 30 percent cheaper than current SSDs that use 25nm NAND Flash cells.

“Our goal is to enable instant, affordable access to the world’s information,” said Tom Rampone, vice president and general manager, Intel Non-Volatile Memory Solutions Group.

“Industry-leading NAND gives Intel the ability to provide the highest quality and most cost-effective solutions to our customers, generation after generation.

“The Intel-Micron joint venture is a model for the manufacturing industry as we continue to lead the industry in process technology and make quick transitions of our entire fab network to smaller and smaller lithographies,” concluded the company's rep.

The two companies haven't yet started shipping 20nm NAND chips, but these have already begun sampling and are expected to reach SSD makers in the second half of this year.

At the same time, Intel and Micron also expect to unveil samples of a 16GB device, creating up to 128GBs of capacity in a single solid-state storage solution that is smaller than a U.S. postage stamp.(via AnandTech)

14 DAY TRIAL //

14 DAY TRIAL //