A company called Kateeva announces the development of a large inkjet printer that can be used to construct displays made out of organic light-emitting diodes (OLED). The device can print OLEDs that are very energy-efficient, flexible and very rich in colors in a manner that is very economical.

Many scientists believe that OLED-based displays will soon replace simple LED displays, since the organic diodes provide better overall performances and life expectancies. Additionally, OLED consume much less power, and produce more beautiful colors.

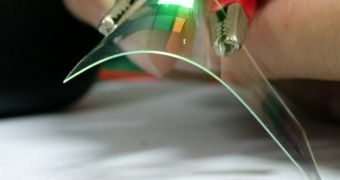

Experts say these diodes can be made from plastic, further reducing their costs. In the future, OLEDs may replace older diodes in TV sets, digital cameras, smartphones, laptops and computer displays. They also hold great promise for the development of flexible and wearable electronics.

One of the main challenges associated with the wide-scale production of OLEDs is that the existing manufacturing process is very complicated and expensive. By using the inkjet printer developed by Kateeva, it may soon be possible to circumvent this problem altogether, Technology Review reports.

The main feature in the new printer is a movable platform that is capable of aligning glass or plastic panels under each print head in the instrument. Each print head contains hundreds of tiny nozzles for depositing the diodes. In this manner, the machine can print OLEDs on a sheet sufficiently large for six 55-inch displays.

The co-founder and president of Kateeva, Conor Madigan, says that the new technology can be easily incorporated into existing display manufacturing lines, meaning that the prospective implementation costs for interested companies are relatively low.

Since the company was founded, back in 2008, engineers have been working on reducing the amount of unwanted particles that are deposited by printing onto the glass or plastic sheets. Over the past 5 years, scientists at Kateeva reduced the amount of such particles 10 times.

This was primarily achieved by moving the entire printing process in an all-nitrogen chamber. This gas prevents OLEDs from being exposed to air or moisture, and therefore reduces unwanted contamination.

Kateeva is the first company to successfully develop an inkjet printer for commercial applications that can actually be implemented. Numerous universities and companies, including Epson, have worked on this over the years, but to no avail.

14 DAY TRIAL //

14 DAY TRIAL //