A team of investigators at the Massachusetts Institute of Technology (MIT), in Cambridge, announces the development of a new method that enables them to create surfaces which are extremely efficient at dissipating heat. This is of extreme importance for solving overheating issues in modern electronics.

Currently, many cooling systems rely on liquids that change their phase. Water, for instance, passes from liquid to gas through boiling in many such systems. However, this solution is impractical for reducing the operating temperature of microchips and other small-scale electronics.

As such, the scientific community has dedicated numerous resources to researching and developing surfaces that maximize the transfer of heat through passive means, as in without consuming energy.

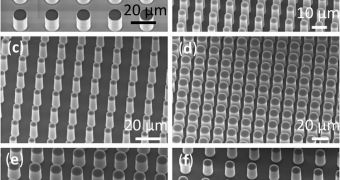

The novel MIT effort was part of this international drive. The team here managed to create a process through which a surface is roughened at the microscale, in a relatively simple manner that significantly increases its ability to transfer heat.

Such surfaces could also find applications in areas such as space exploration. They could be installed on telescopes that need to be cooled down to extreme temperatures in order to work properly, and which currently have short life span because of fuel limitations.

Previously, scientists found that patterning surfaces at the nanoscale could also increase heat transfer, but that process is more complex and costly than creating similar patterns at the microscale. The MIT group believes that the new method could be improved even further.

Graduate student Kuang-Han Chu, postdoctoral researcher Ryan Enright and associate professor of mechanical engineering Evelyn Wang co-authored a new paper on the microscale patterning method, which appears in the June issue of the esteemed scientific journal Applied Physics Letters.

According to Wang, the phase-change process used by many modern cooling systems is very complex, which is why understanding it in detail took so many decades. It's only now that we know enough about it in order to control it by changing the surfaces of materials we use to make them.

In a study they conducted on a test cooling system that used water, the researchers obtained a doubling of the maximum heat dissipation amount previously possible, after patterning the surfaces at the microscale.

“This development opens doors to a new class of surface structures combining micro- and nanoscale features,” comments Rochester Institute of Technology professor of mechanical engineering Satish Kandlikarat, who was not a part of the new study.

14 DAY TRIAL //

14 DAY TRIAL //