A turbocharger is a force-induced system used to enhance the mass of air entering the combustion chamber of a typical internal combustion engine. Basically, a turbocharger is a compressor that, by forcing more air into the cylinder, enables an increase in the amount of used fuel, so that more explosion power is generated in order to improve the engine's power to weight ratio at high speeds.

Typical turbochargers consist of a small turbine and a compressor, whose drive shafts are connected together, with the turbine powering the compressor. By doing so, the turbocharger can reach spins of up to 150,000 rotations per minute, as opposed to turbocharger designs that are powered from the drive shaft of the engine and use only a compressor that reaches rotation speeds some 30 times lower. Also, turbocharger systems using designs involving a turbine and a compressor are known to reach higher temperatures than other designs, since the turbine is driven by the exhaust gas of the engine.

Increasing the power output of an engine immediately translates into an increase in the amount of used air and fuel. This can be easily done by adding more cylinders to the engine, or by increasing the volume of the existing ones. However, since these two types of power increase methods usually lead to a rise in the engine's weight, turbochargers are preferred as an alternative.

How it works

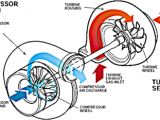

As earlier said, typical turbochargers rely on a turbine and a compressor to operate efficiently, one driving the other. Exhaust gas resulted from the engine burning petrol, or other types of fuel, is usually dumped directly into the atmosphere. However, when using a turbocharger system, the gas is first redirected through the turbine of the turbocharger which, in turn, reacts by starting to spin. At the same time, because the turbine and compressor are connected to each other, the latter is also forced to spin.

As the compressor rotates, is picks up air from the atmosphere, compresses it, and forces it into the engine's cylinders. In engines without turbocharger systems, the air pressure entering the cylinders registers 14.7 psi at sea level. Turbochargers are able to provide with an additional 6 to 8 psi, which basically translates into a boost of power of up to 40 percent.

14 DAY TRIAL //

14 DAY TRIAL //