A Steam engine is an external combustion heat engine, used to convert heat energy into mechanical work. It was first invented about three centuries ago and quickly became widespread throughout the world, mostly used for steam locomotives. Even today steam engines are extremely popular, although they are not used anymore to power train locomotives and their design has deviated somehow from the original concept.

Steam engines are currently responsible for producing 86 percent of the total electric energy in the world. The pistons used to produce mechanical work have been replaced by steam turbines; although very hard to build, steam turbines are much more efficient than pistons, take less material to build and can be easily scaled up.

The first working steam engine was presumably built by Thomas Newcomen and James Watt in 1705, and acted as the foundation for the first Industrial Revolution.

The boiler

In order to make a steam engine work, you first need a boiler to turn liquid water into steam. Boilers come in two basic constructions: fire tube and water tube.

The fire tube approach involves using a water tank which is perforated by tubes through which gases generated by burning coal or wood are circulated. The problem is that because the water tank is under extreme pressure, the whole fire tube boiler may explode. Fire-tube steam engines were very common during the 1800s.

Water tube boilers, on the other hand, use a construction in which a fire tank containing hot gases houses a series of tubes, water being circulated through them.

Operation

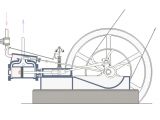

The steam produced by the boiler is sent into the piston of the steam engine. High-pressure steam enters a slide valve which moves alternatively between two positions - the valve is operated by the piston itself through a control rod. After clearing the valve, steam enters the piston through one of the two vents located at each end and starts pushing the piston. At the same time, air is evacuated out of the piston through the other vent.

As the piston reaches the air venting, it pushes the control rod of the slide valve towards its second position, thus reversing the roles of the two vents. The steam vent becomes the air vent and vice versa. Again, steam is pushed inside the piston, causing it to move towards its other end. The cycle repeats itself until the steam supply to the piston is cut off, or the pressure of the steam is not enough to operate the piston.

The linear motion of the piston is then converted into circular motion with the help of a connecting rod linked between the piston rod and the crank of the flywheel.

14 DAY TRIAL //

14 DAY TRIAL //