Brushless DC electric motors are a design variation derived from the old brushed electric motors except that the relative motion of the rotor and the stator is reversed. To understand how this is done, one must first understand the basic construction and operation of a brushed DC electric motor. Typical DC motors imply the use of two magnetic field generation systems. One is placed on the rotor, or the part that is rotating, and the other one on the stator, the part of the motor that maintains a relative position.

The stator generates a magnetic field with the help of a pair of permanent magnets, inside which a spinning armature is posted. The armature is powered through two electrodes connected to a split ring commutator brushing against a series of brushes connected to a DC power supply. As the armature is being powered and current starts circulating through the coil, a secondary magnetic field is generated and interacts with the one produced by the permanent magnets.

As a result, the armature is spun by 180 degrees. The brushes then change the polarity of the electric current circulating through the coil and the armature is being spun by another 180 degrees, thus completing a rotation. Through this extremely simple design, the rotor is being spun continuously until power is shut down.

There is a problem though. The brushes providing the current to the split ring commutator experience friction and will eventually wear out, triggering a malfunction. The current commutation between the two electrodes posted on the split ring commutator produce sparks as well as both electrical noise and acoustic noise. The speed rotation is limited and the fact that the armature is rotating impedes the cooling of the coils producing the secondary magnetic field, not to mention the fact that precision is limited to the number of brushes.

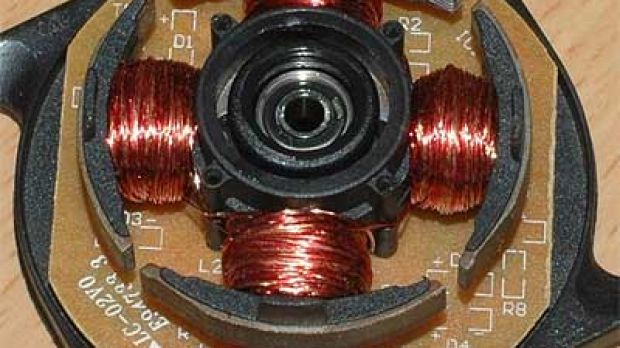

All of these disadvantages can be simply resolved by reversing the roles of the rotor and the stator, meaning that the construction remains roughly the same, except that you're not using brushes, and the stator rotates while the rotor maintains relative position. Some of you may say 'but how will the current commutation be made?'

With brushless DC electric motors current commutation is no longer done mechanically as in the case of brushed electric motors. Instead the current polarity alternation is made with the help of special power sources using power transistors.

14 DAY TRIAL //

14 DAY TRIAL //