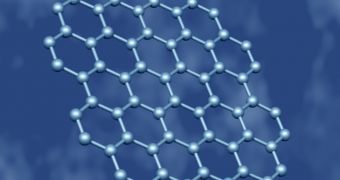

A new nanocomposite polymer with remarkable thermal and mechanical properties has been developed by Northwestern University and Princeton University by incorporating functionalized, exfoliated graphite sheets. The material also conducts electricity and may be used to develop thermally stable optically transparent conducting polymers to coat solar cells.

The study originally started several years ago when McCormick School of Engineering teamed up with Princeton researchers. The advantages of such a collaboration were obvious, since the McCormick researchers had great experience with polymer nanocomposites while Princeton researchers had developed a way to exfoliate graphite in order to create functionalized graphene sheets.

All previous studies focused in this particular respect have failed to improve the properties of nanocomposite materials because researchers didn't have the required experience to exfoliate graphite. Most of the obtained graphite sheets were either too rigid or had a minimal surface area, thus could not affect the properties of the polymer.

Albeit by achieving a concentration of 0.05 percent of exfoliated graphene sheets, researchers proved that the thermal stability of the polymer can be increased by 30 degrees. Another increase in concentration by 0.01 percent rendered the material 33 percent stiffer than previously thought possible.

The results show that graphene stabilizes the polymer by changing large regions of the polymer radiating out from the nanoparticle surface in a network structure. The new thermal and mechanical properties of the polymer appear to be similar to those of other nanocomposite polymers using functionalized single-wall nanotubes, although the new technique is much cheaper and easier to implement.

"This is the first time people have been able to demonstrate dramatically altered properties like this with really small quantities of graphite-based materials", says Cate Brinson, Jerome B. Cohen Professor of Mechanical Engineering.

The graphene sheets contained in the polymer also help the material to stop water and other gases from penetrating all the way through it, which could change its thermal and mechanical properties, making it durable and a candidate for a wide range of applications.

"I think it has enormous potential. With the ready availability of graphite and the properties we have demonstrated, this new material will enable significant structural scale use of carbon-based nanocomposites", said Briston.

14 DAY TRIAL //

14 DAY TRIAL //