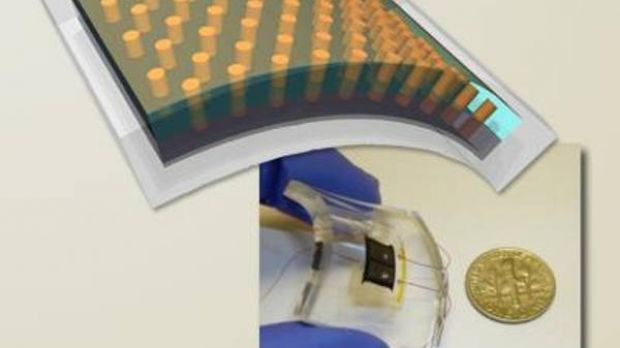

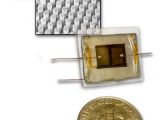

A new design for growing optical semiconductors, created by experts at the US Department of Energy's (DOE) Lawrence Berkeley National Laboratory (LBNL) and the University of California in Berkeley (UCB), will make efficient, low-coast, and flexible solar cells and panels a reality in the future. In the new process, the semiconductors are “grown” in arrays of nanoscale pillars, which in themselves form single crystals. The sizes of these constructs can be measured at the nanoscale, in billionths of a meter.

“To take advantage of abundant solar energy we have to find ways to mass-produce efficient photovoltaics. Single-crystalline semiconductors offer a lot of promise, but standard ways of making them aren't economical,” LBNL Materials Sciences Division faculty scientist Ali Javey explains. He is also a UCB professor of electrical engineering and computer science. He further adds that the largest advantage the new technology has is that it's in 3D, meaning that the surface it exposes to sunlight is not just long and wide, but also deep.

Computer models that the researcher ran showed that, at least in theory, the new constructs should be far more effective than the old ones, simply because they could separate and trap photons better, and also because they were better at carrying the charged electrons that were created, in the form of electrical current. The arrays themselves, on account of the larger surface they expose to the light, are more sensitive to photons than any existing type.

“Unfortunately, early attempts to make photovoltaic cells based on pillar-shaped semiconductors grown from the bottom-up yielded disappointing results. Light-to-electricity efficiencies were less than one to two percent. Epitaxial growth on single crystalline substrates was often used, which is costly. The nanopillar dimensions weren't well controlled, pillar density and alignment was poor, and the quality of the interface between the semiconductors was poor,” Javey adds.

“There are lots of ways to improve 3-D nanopillar photovoltaics for higher performance, and ways to simplify the fabrication process as well, but the method is already hugely promising as a way to lower the cost of efficient solar cells. There's the ability to grow single-crystalline structures directly on large aluminum sheets. And the 3-D configuration means the requirements for quality and purity of the input materials are less stringent and less costly. Nanopillar arrays are a new path to versatile solar modules,” he concludes.

14 DAY TRIAL //

14 DAY TRIAL //