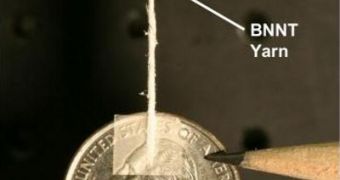

Scientists at the US Department of Energy's (DOE) Thomas Jefferson National Accelerator Facility, the NASA Langley Research Center, and the National Institute of Aerospace have recently announced the development of a new class of materials. Boron-nitride yarns are threads of interlocking fibers at the nanoscale that hold great promise for creating stronger body armors, and even spacecraft heat shields, among other things. The team used Jefferson Lab's Free-Electron Laser to obtain the new structures, which have been produced in a very stable manner that opens the door for a large array of applications.

“Other labs can make really good nanotubes that are are short or really crummy ones that are long. We've developed a technique that makes really good ones that are really long,” Langley staff scientist Mike Smith says. What the team did was to basically develop a completely new synthesis method for high-quality boron-nitride nanotubes (BNNT). These structures are difficult to produce because they have a crystalline structure and also a very small diameter. As such, making it stable posed a double-challenge, the scientists say.

The new technology has been named the pressurized vapor/condenser (PVC) method. The production process is fairly simple, but it needed this boost like a fish needs water. All that is required is a chamber filled with nitrogen gas, a powerful laser, and a condenser material. A beam of light is fired inside the chamber, into a boron. The highly energetic light vaporizes the target and transforms it into boron gas, which then floats freely inside the chamber. The condenser material, usually a cooled metal wire, is then inserted in the mix. This forces the boron vapors to cool and form droplets, which then combine with nitrogen and begin the BNNT self-assembly process.

“They're big and fluffy, textile-like. This means that you can use commercial textile manufacturing and handling techniques to blend them into things like body armor and solar cells and other applications,” Jefferson Lab staff electrical engineer Kevin Jordan says. “Theory says these nanotubes have energy applications, medical applications and, obviously, aerospace applications,” the expert adds. “Some of these things are going to be dead ends and some are going to be worth pursuing, but we won't know until we get material in people's hands,” Smith concludes.

14 DAY TRIAL //

14 DAY TRIAL //