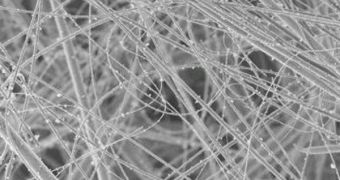

Scientists were recently able to create a new method of producing glass nanofibers, one that relies on technology known as “laser spinning”. The group, made up of researchers from the University of Vigo, the Rutgers University, in the United States, and the Imperial College London, in the United Kingdom, also managed to create the nanofibers out of bioactive glass, which is the same material used in medicine, to promote the regeneration of bones.

“Laser spinning makes it possible to produce glass nanofibers of compositions that would be impossible to obtain using other methods,” explains UV researcher Felix Quintero, who is also a coauthor of the new study. The findings are detailed in a front-cover paper, published in the latest issue of the respected scientific journal Advanced Functional Material. The main highlights of the new method are the use of a high-energy laser, which is aimed at a precursor material, and then made to heat it. A powerful gas current is then used to lengthen and cool the resulting super-fine filament of material.

Another great feat that the new technique has is its ability to be used in relatively common environmental conditions, as well as the fact that almost all of its processes can be easily tweaked. This means that the scientists operating the lasers can have more control over the finished product, which is something you don't see very often in the nanotechnology industry. Usually, particles or tubes at this scale are grown, and the process can only be mildly influenced through external factors.

The group's achievement could in the near future be used in hospitals as well, the researchers say. Because of its nanometric structure, the bioactive variety of glass nanofibers can be made to be elastic and long, which means that it could promote bone proliferation. According to previous research, new bone cells find it a lot easier to get a grip on, and grow in, materials at the nanoscale. The new technology could also have other uses, such as producing fire-retardant fabrics, CO2 capture systems, and even composite materials, which currently require nanofiber reinforcement, ScienceDaily reports.

14 DAY TRIAL //

14 DAY TRIAL //