Ever since graphene was first discovered in 2004, experts have realized the immense potential that the new carbon-compound has for constructing new generations of computer processors and semiconductor materials. However, creating large amounts of the stuff has proven to be a very complex task, which has largely remained uncompleted thus far. Now, experts from the University of Texas in Austin (UTA) have managed to create the first large-area graphene layer, using copper as a substrate.

“Graphene could lead to faster computers that use less power, and to other sorts of devices for communications such as very high-frequency (radio-frequency-millimeter wave) devices. Graphene might also find use as optically transparent and electrically conductive films for image display technology and for use in solar photovoltaic electrical power generation,” UTA Physical Chemist and Professor Rod Ruoff explains. He has been one of the corresponding authors for a new study detailing the methodology used for the innovation, which was published online on May 7th, in the respected journal Science.

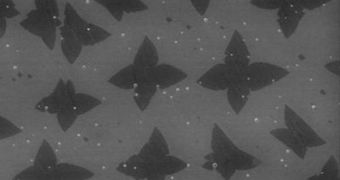

As a material, graphene has a peculiar structure, and equally odd chemical and physical properties. Its aspect resembles a matrix of hexagonal structures, which connect to each other through weak links. It conducts electricity very effectively, and, so, it could be used in a broad range of applications, from memory system, logic, analog, and opto-electronic devices to super-capacitors and new generations of batteries, ScienceDaily reports.

“There is a critical need to synthesize graphene on silicon wafers with methods that are compatible with the existing semiconductor industry processes. Doing so will enable nanoelectronic circuits to be made with the exceptional efficiencies that the semiconductor industry is well known for,” Ruoff adds.

For the recent copper-based graphene construct, the experts have demonstrated that the carbon compound can be deposited on such a substrate in square-centimeter portions. They have also revealed that their approach ensures that only up to five percent of such a surface receives more than one layer of graphene (as in they get double or triple layers).

“We used chemical-vapor deposition from a mixture of methane and hydrogen to grow graphene on the copper foils. The solubility of carbon in copper being very low, and the ability to achieve large grain size in the polycrystalline copper substrate are appealing factors for its use as a substrate – along with the fact that the semiconductor industry has extensive experience with the use of thin copper films on silicon wafers. By using a variety of characterization methods, we were able to conclude that growth on copper shows significant promise as a potential path for high-quality graphene on 300-millimeter silicon wafers,” the UTA expert shares.

The research was mostly funded by the South West Academy for Nanoelectronics (SWAN) and the DARPA CERA Center, both of which are directed by Electrical and Computer Engineering Professor Sanjay Banerjee, also a co-author of the new study. The state of Texas also contributed to the research, which joins a number of others recently completed. Together, the innovations could finally set research teams around the world on a straight path towards creating the long-awaited new processors, displays, and semiconductor materials.

14 DAY TRIAL //

14 DAY TRIAL //