When it comes to 3D printing things out of metal, there are two technologies one can rely on, though some may call them the same: selective laser sintering (SLS) and selective laser melting (SLM).

Both technologies allow for significant detail level, as well as materials with mechanical qualities good enough and safe enough to use in jet engines and the like.

However, there are certain advantages that the “cold spray” approach brings to the table, and we don't just mean it being cheaper.

The technique uses metal components engineered “to a very high standard” in order to create very finely crafted metal parts at room temperature.

In other words, the heat bonding needed in SLS and SLM is not required here, meaning that components won't be warped or damaged, and no gauged temperate environments are necessary, removing another hassle and expense.

How cold spray 3D printing works

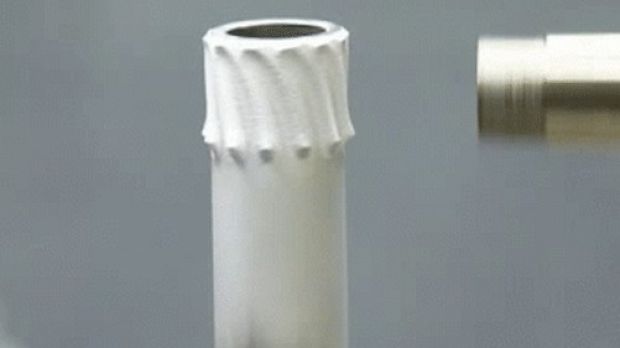

Originally developed in Russia in mid-80s, the technique uses helium to print metal components by spraying metal powders at high velocities.

Mostly used for repairs, the method is key in repairing US army helicopters which have parts made of magnesium alloy.

General Electric refined the technology back in November 2014, to produce high quality deposits made of high temperature Ni and Ti alloys.

Metal powders are deposited at Mach 4 speeds on the surface of the material that needs repair (like jet plane parts) at a temperature below the melting point. It can also be adapted for rotors, blades, shafts, propellers, and gear boxes easily enough.

3D printing, however, can go much further than that. Dublin researchers are now picking up the proverbial gauntlet.

New funding granted

Researchers in the Department of Mechanical and Manufacturing Engineering at Dublin, Ireland’s Trinity College have been awarded around three quarters of a million dollars by the European Space Agency (ESA).

Cold Spray 3D printing technologies will be developed for use in space exploration, but printing car components and inventing better frying pans (which don't stick) should come naturally over time as well.

New cold spray nozzles, gas systems, and process simulations will come first. After that, even the sky won't be the limit.

Below you'll see a video of the General Electric cold spray technology in action. It's a pretty short one, but it doesn't need to be long to show what it's all about.

14 DAY TRIAL //

14 DAY TRIAL //