There is currently no doubt in the international bioengineering community that the future of health care is in personalized medicine. This means that future transplant patients, for example, will no longer have to wait on extensive donor lists in order to get the kidney, heart, liver or lung they need to survive. The procedure could simply be to harvest a few stem cells, and then grow them in the lab, on a scaffolding designed specifically for this purpose. The strive now is to determine which material suits growing bone, cartilage and soft tissue best.

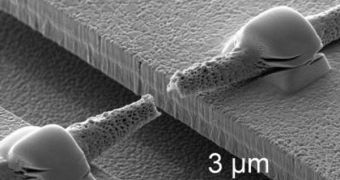

Some of the most promising materials are a class known as non-wovens, which are basically fabric-like materials, constructed from long fibers, bonded together by chemical, mechanical, heat, or solvent treatment. The porous design could be made entirely out of polymer fibers in the future, on which, for example, cartilage tissue and blood vessels could grow. Shaped in the needed manner, the scaffolding could, in the end, produce a batch of tissue that could be immediately used, without having to worry that the recipient's immune system will reject it, and without having to make the patients take immunosuppressive drugs for the remainder of their lives, thus opening doors for nasty infections.

One of the main challenges of artificially creating a tissue is that you have to make it as resistant as the one you're replacing. That is to say, if you're constructing a knee cartilage, for example, it has to be able to withstand all the pressure and tension a usual one does – and this means that you have to grow it from the lab stages to handle any demands. This is very important because, once in the body, the scaffolding reabsorbs into the patient's system, and only the new tissue remains. And it has to perform flawlessly.

German researchers at the Fraunhofer Institute for Mechanics of Materials IWM, in Freiburg, have recently developed a computer model that shows exactly how the new cells penetrate the non-wovens. The model could help devise more effective and resistant scaffolding materials. “The simulation reproduces the mechanical properties of the fleeces and the transport processes – the software can therefore also calculate how nutrients are transported to the cells and metabolic products are transported away from the cells when a liquid flows by. Understanding these processes can be helpful for cell culture,” IWM Group Manager Dr. Raimund Jaeger explains.

14 DAY TRIAL //

14 DAY TRIAL //