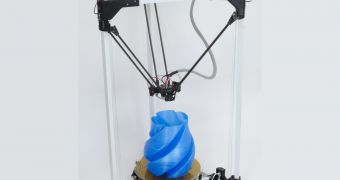

Like pretty much every other device type out there, 3D printers started out as big and bulky things, but they've steadily been getting better, lighter and smaller. The BI V2.0 3D printer has one extra asset though: it can clone itself.

Well, it sounds really wondrous put that way, but it's true. The BI V2.0 3D printer from Boots Industries can make replicas of all its parts on its own. Said parts can then be put together in a period of 30 minutes.

And it's all done without having to string pulleys or wire the supporting towers. All for ease of use.

Also, the hot end of the printer has a modified 4 mm push fitting that lets the PTFE tube lock in place, thus enabling high-speed 3D printing and making it impossible for clogging to occur.

What's more, the BI V2.0 3D printer can operate independent of a computer, through use of an integrated liquid crystal display (LCD) controller.

Said LCD has key functions for the 3D printing speed, temperature and other parameters. A 4 GB SD can hold the print files (up to 2,500).

Currently, the Boots Self-Replicating 3D Printer can be found in a fund-raising campaign on Kickstarter.

Objects can be made out of PLA, ABS, Nylon and other materials with it, and the extruder temperature can reach 240 degrees Celsius / 464 degrees Fahrenheit.

To make sure that you get one during the first delivery wave, assuming the fund-raising goal of $30,000 / €21,842 is reached (which will probably be, since money is just a few grand short right now), you need to pledge $80 / €58.24.

All in all, for a company founded in 2012 by Jean Le Bouthillier, MSc and Francois Crete, BEng, Boots Industries is doing quite well for itself already. With luck, it might become a well-known trademark like MakerBot.

14 DAY TRIAL //

14 DAY TRIAL //