Scientists from the Stanford University announce the development of a new manufacturing technique, that allows them to produce dye-sensitized thin-film solar cells which are up to 20 percent more efficient at converting photons into electrons than exist cells of the same type.

The reason why dye-sensitized cells are so important is that they offer a cheaper alternative to the conventional silicon cells currently in use. However, they are considerably less efficient.

But now, thanks to the new method developed at Stanford, these cells may become capable of trapping more light then ever before, a thing that would make them comparable to their silicon counterparts.

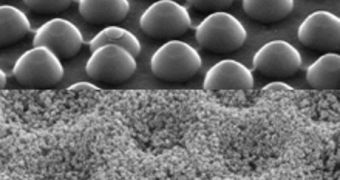

Experts with the university turned to using an especially-designed metal reflector for the job. The material is a very thin silver film, that features an array of nanoscale bumps on its surface.

This new material is then used to coat the back surface of solar cells, the investigators added, so that even more light than before gets trapped inside. The overall efficiency of the cell is then entirely up to the dye being used.

“We get about 5 to 20 percent more absorption depending on the dye,” explains Michael McGehee, who is the director of the Stanford Center for Advanced Molecular Photovoltaics.

The expert was also the leader of the investigation, details of which were recently published in the latest online issue of the esteemed scientific journal Advanced Energy Materials.

At this point, some of the best dye-sensitized thin-film cells reach 11 percent efficiency. If the Stanford team could market cells of this category featuring 30+ percent efficiency, then it would hit the jackpot.

What's even more interesting is that existing thin-film cells of this type now use liquid electrolytes, which can easily leak from their enclosures. Solar cells produced using solid electrolytes managed to reach only 5 percent conversion efficiency.

“They took the best solid-state dye cell they could, and made it better,” says of the effort the Stanford team made David Ginger, who holds an appointment as a chemistry professor at the University of Washington.

“Even better, they did it using technology and methods that could potentially be used in a production environment,” he goes on to say, quoted by Technology Review.

“This is the first time that plasmonic structures have been applied to solid-state dye-sensitized solar cells, with a substantial increase in cell efficiency being reported,” adds Australian National University research fellow Kylie Catchpole, who is also working on thin-film solar cells.

14 DAY TRIAL //

14 DAY TRIAL //