3D printing technology, or additive manufacturing, as it is otherwise known, doesn't need to be used just for random baubles. Indeed, it was initially employed in assembly factories anyway.

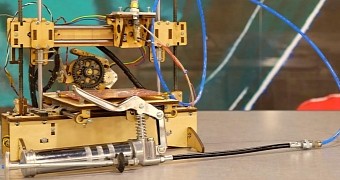

A team called Maizena 3D has recently taken a step back towards the direction of those “roots” by creating a new type of 3D printing extruder.

Instead of a device that uses electricity to superheat plastic filament, the extruder runs on air and can force out a mixture of corn starch and water through a standard 3D printer nozzle.

For those who want specifics, the 0.6 mm nozzle employs an air pressure of 100 psi at 90 degrees to extrude corn starch much like normal 3D printers do with plastic filament / pellets. The funny part is that the bulk of it is based on a grease gun.

The first order of business (assuming that they get enough people interested) to start producing is to make large objects very quickly, as well as noise dampening and insulating products.

That the material is very eco-friendly and soluble in water is another bonus, although it also poses its own drawbacks. Fortunately, anti-rain canopies are easy enough to procure.

That corn starch is really easy and cheap to get is another bonus. You can get a pound / 0.45 kilos at any grocery store for $1.5 / €1.20.

14 DAY TRIAL //

14 DAY TRIAL //