Hybrid electric vehicles of the future may contain flywheels rather than batteries, if new research efforts by automakers such as Volvo and Jaguar are successful. The old flywheel technology could enable electric vehicles to operate even more efficiently than they do today.

In addition, they could also aid in acceleration, which is when most batteries lose a lot of their charge. It is estimated that introducing flywheels in hybrid engines could contribute to reducing fuel consumption by as much as 20 percent.

At the same time, the cost of building such an engine would be only 33 percent that of building a standard hybrid electric one. Volvo is extremely advanced in this research. Officials at the company announced that they will being testing a concept vehicle outfitted with flywheels this fall.

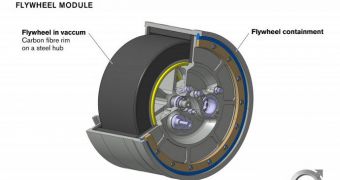

Using flywheel technology for cars is nothing new. The main idea in using this method is have some of the energy from the wheels transmitted to a flywheel, which is made to move at high speeds. When required, a transmission couples the flywheel to the wheels again, transferring the stored energy back.

The main issue with this system is friction. When General Motors attempted to engineer a flywheel system back in 1982, the company discovered that fuel efficiency was only improved by half of what engineers expected, so the project was dropped.

However, at this point, technological advancements could make the technology feasible, Volvo vice president of powertrain engineering Derek Crabb believes. “Industry has gone from being skeptical to thinking it can be done, but there are enormous challenges,” he says.

One of the main advantages that using flywheels has over conventional electric batteries is the fact that they are way smaller, and able to deliver even more punch. However, flywheels are notoriously unreliable when it comes to supplying energy to a moving system for prolonged periods of time.

“Most hybrids with batteries provide a 15- to 25-kilowatt boost of power. The flywheel can deliver 60 kilowatts in a way smaller package,” explains Andrew Atkins, who is the chief engineer of technology at UK-based engineering company Ricardo.

When and if flywheels make it to the market, they will go up against lithium-ion batteries, which are currently being improved using nanotechnology, as well as increasingly powerful and cheap ultracapacitors.

But automakers are convinced that improving flywheel technology could enable cheap, large-scale manufacturing of cars that rely on it for motion. Combining this with methods of harvesting energy from brakes could result in even more power efficiency, Technology Review reports.

14 DAY TRIAL //

14 DAY TRIAL //