3D printing is the most popular technology right now, since it's new and could be used for basically anything, so what better way to blow people's minds than to combine it with the most legendary material of these times?

Graphene 3D Labs has done just that, or at least come up with a preliminary technology for using graphene in 3D printing.

Graphene is considered the holy grail of the next generation of technology, the potential bridge towards sci-fi-like inventions.

It can be used in ultra-durable constructions, superconductors, superior storage devices and everything in between.

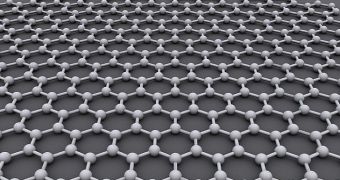

Scientifically, it can be described as a material entirely composed of carbon atoms, similar to graphite. But while graphite is a three-dimensional crystalline arrangement containing around 3 million layers of graphene, graphene is a two-dimensional crystal with the thickness of a single atom.

And said atoms are arranged in a hexagonal honeycomb with just 0.1 nanometres between each atom. The thickness is of 0.3 nanometers.

Graphene 3D Labs has filed a provisional patent application for using graphene-enhanced material in 3D printing.

Electrodes will probably be the first things created that way, since graphene is highly conductive, strong and has a high specific surface area.

Lomiko Metals Inc. is basically the owner of Graphene 3D Lab and has very high hopes with this invention.

“This patent application is the result of a diligent effort on behalf of our team. It opens up a clear path toward the commercialization of graphene,” stated Daniel Stolyarov, Graphene 3D Labs’ CEO.

“It is important that our proprietary technology is accepted by consumers in this market and that we find a method of creating graphene-infused filaments of outstanding quality at a reasonable cost. We rely on high quality graphite from Lomiko’s Quatre Milles Property as the base material for producing graphene nanoplatelets, due to their cost and consistency in quality.”

14 DAY TRIAL //

14 DAY TRIAL //