Human-powered submarines (like underwater bicycles, of a sort) will never be used for actual explorations, but there are races held with them every year in various places, like Florida and, in this case, an indoor channel that the U.S. Navy uses to test new ship designs.

It goes like this: teams of one or two people are tasked with creating their own submarine from scratch, then test it for the first time in a race against other teams.

The race happens through a 10-meter / 30-foot section of the aforementioned indoor channel. Each team is allowed to run their sub through the course for as many times as they want during the five days of the contest.

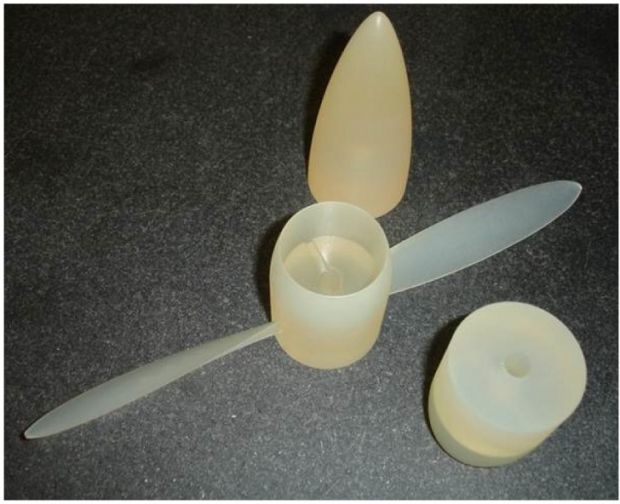

Participating every other year (the race itself is a biannual event) is the University of Michigan. The latest team to enter the contest had trouble creating the propeller blade, specifically with the conversion of a point cloud file to one that could be used to guide the cutter path on a CNC machine.

Eventually, they got outside help (Burton Precision), gained through the brother of one of the team members, and used 3D printing technology to make the propeller. A 3D Systems ProJet 3500 HDMax printer was utilized, while the substance used for the propeller itself was a plastic called, oddly enough, Crystal.

The next human-powered International Submarine Race will be held between June 22 – 26, 2015. The design may very well evolve by then.

14 DAY TRIAL //

14 DAY TRIAL //